Table of Contents

1. Introduction

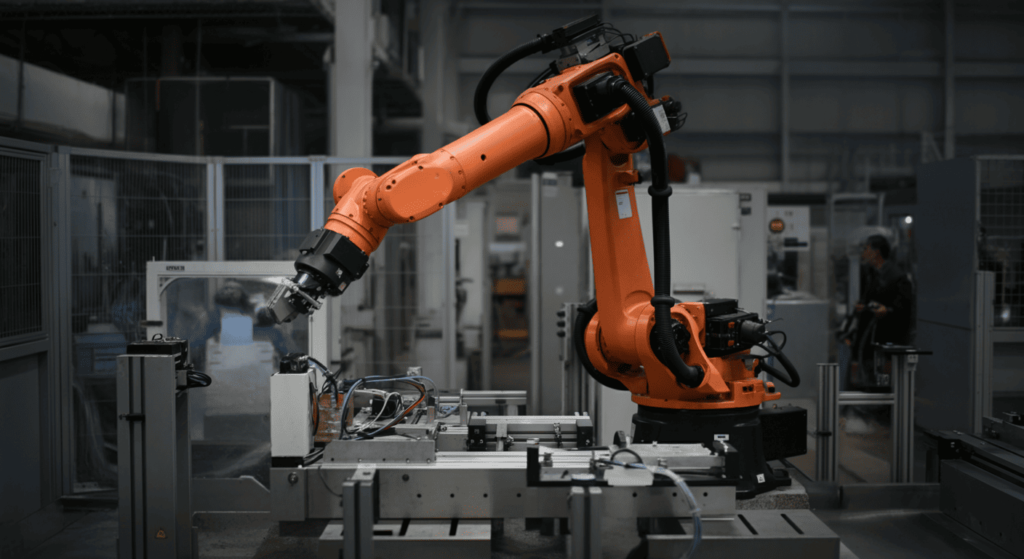

Ever wondered how products move from raw materials to your hands with near-flawless precision? Meet the transformative force called Automated Manufacturing. In an age dominated by speed, agility, and advanced robotics, automation has transitioned from a futuristic concept to a fundamental backbone of modern industries. Whether it’s automotive assembly lines churning out vehicles or high-tech facilities producing microchips, automated manufacturing is redefining what’s possible in production efficiency.

In this comprehensive guide, you’ll uncover how automated manufacturing works, why it matters more than ever, and how it can help companies of all sizes stay competitive. From real-world examples to practical steps for implementation, we’ll dive deep into everything you need to know. By the end, you’ll walk away with a clear understanding of how to leverage automation for streamlined operations—and maybe even a fresh perspective on how the future of work will evolve.

2. Automated Manufacturing: A Quick Overview

Let’s cut straight to the heart of the matter. Automated Manufacturing refers to the use of technology—like robotics, computer software, and control systems—to operate and manage manufacturing processes with minimal human intervention. The goal? Improve efficiency, quality, and flexibility while cutting costs.

- Primary Objective: Enhance production throughput without compromising on quality.

- Key Enabler: Seamless integration of advanced hardware (like robots) and software (like AI-driven controls).

- End Result: Consistent product quality, reduced error rates, and the ability to adapt swiftly to market demands.

3. The Evolution of Automated Manufacturing

Automation in manufacturing isn’t new. It traces back to the early days of industrialization, even before Henry Ford’s revolutionary assembly line concept. Let’s take a stroll through history:

- Early Mechanization (18th-19th Century)

- The steam engine era brought basic mechanization. Machines replaced rudimentary hand tools, boosting output but still requiring significant manual labor.

- Mass Production (Early 20th Century)

- Henry Ford’s assembly line in 1913 showcased standardized workflows. This system demanded repetitive tasks but ramped up production speed dramatically.

- First Wave of Automation (1950s-1970s)

- The introduction of programmable logic controllers (PLCs) and basic robotic arms in automotive factories set the stage for “lights-out” operations.

- Manufacturing lines became safer and faster, although still limited in flexibility.

- Digital Revolution (Late 20th Century)

- Computers and CNC (Computer Numerical Control) machines offered better precision and customization.

- Electronics manufacturing—like the semiconductor industry—rapidly expanded due to these advancements.

- Industry 4.0 & Smart Factories (21st Century)

- The convergence of IoT (Internet of Things), AI (Artificial Intelligence), and advanced robotics.

- Real-time data analytics enables predictive maintenance, and cloud computing offers scalable solutions.

From humble steam-powered machines to AI-driven robots, automated manufacturing has steadily evolved to meet ever-growing market demands.

4. Key Technologies Powering Automation

The modern landscape of automated manufacturing is defined by several cutting-edge technologies, each serving a unique role in streamlining the production process:

4.1 Robotics and Cobots

- Industrial Robots: Think multi-axis arms used for welding, assembly, or painting.

- Collaborative Robots (Cobots): Designed to work alongside humans, these safer, more user-friendly robots are revolutionizing small-scale and specialized tasks.

4.2 AI and Machine Learning

- Quality Control: AI-powered cameras detect defects in milliseconds, minimizing product waste.

- Predictive Maintenance: Machine learning algorithms forecast equipment failures, reducing downtime.

4.3 IoT Sensors

- Real-Time Monitoring: Sensors feed data to cloud platforms, allowing immediate response to anomalies.

- Efficiency Tracking: Track energy usage, production speed, and other metrics to optimize operations.

4.4 Advanced Software Platforms

- Manufacturing Execution Systems (MES): Bridges the gap between the shop floor and management, ensuring real-time visibility.

- CAD/CAM Tools: Seamlessly transfer product designs into automated production lines.

4.5 Additive Manufacturing (3D Printing)

- Customization: Create complex geometries and prototypes quickly.

- On-Demand Manufacturing: Reduces inventory by printing parts as needed.

Each technology complements the other, forming an interconnected ecosystem of hardware, software, and real-time analytics.

5. Types of Automated Manufacturing Systems

“Automation” is a broad term. In practice, you’ll find different levels and types of automation depending on industry requirements, batch sizes, and product complexity. Here are the primary categories:

5.1 Fixed Automation

- Example: High-volume assembly lines for cars or consumer electronics.

- Characteristics: Extremely high production rates, minimal flexibility in product changes.

- Ideal For: Large, consistent demand over extended periods.

5.2 Programmable Automation

- Example: CNC machine tools in metal fabrication.

- Characteristics: Greater flexibility than fixed automation, but reprogramming can be time-consuming.

- Ideal For: Batch production where product variations occur but not too frequently.

5.3 Flexible Automation

- Example: Robotic arms that can switch tasks on the fly.

- Characteristics: Real-time adaptability, highly efficient for small to medium batch sizes.

- Ideal For: Markets where customization or short runs are vital.

5.4 Integrated Automation

- Example: Smart factories incorporating IoT, AI, and advanced robotics in a seamless pipeline.

- Characteristics: Autonomous decision-making, self-optimizing processes, minimal human intervention.

- Ideal For: Cutting-edge industries needing a holistic, data-driven approach.

6. Core Benefits of Automated Manufacturing

Implementing automated manufacturing can feel daunting, but the rewards often outweigh the challenges. Let’s break down the key advantages:

- Enhanced Productivity

- Machines can operate 24/7 with minimal breaks, significantly boosting output.

- Consistent Quality

- Automated systems reduce human error, leading to uniform product standards.

- Reduced Labor Costs

- While skilled labor remains crucial for oversight, automation cuts down on repetitive manual tasks.

- Better Safety

- Robots take on hazardous tasks, lowering the risk of injuries to human workers.

- Data-Driven Insights

- Real-time analytics facilitate quick decision-making, saving time and resources.

Remember, each company’s situation is unique. A small firm might adopt collaborative robots to assist human operators, while a global enterprise might invest in fully integrated smart factories.

7. Real-World Applications

It’s one thing to talk about automated manufacturing in theory; it’s another to see it in action across various industries. Below are some prominent examples that highlight its far-reaching impact:

7.1 Automotive Industry

- Assembly Lines: Automated guided vehicles (AGVs) transport parts. Robotic arms handle tasks like welding and painting.

- Engine Production: Precision machining with CNC tools ensures uniform engine components.

7.2 Electronics and Semiconductor Manufacturing

- Chip Fabrication: Automated wafer-handling robots operate in ultra-clean environments.

- Circuit Board Assembly (SMT): Surface-mount technology lines place thousands of components per hour with near-perfect accuracy.

7.3 Food & Beverage

- Packaging: Robotic systems handle fragile and perishable items, minimizing contamination risks.

- Quality Control: AI-powered vision systems detect anomalies in product size, color, or texture.

7.4 Pharmaceuticals

- Sterile Environments: Automation reduces human contact, vital for maintaining stringent cleanliness standards.

- Automated Dosing and Sorting: Consistency and traceability become significantly easier.

7.5 Aerospace

- High-Precision Fabrication: Automated drilling and riveting systems meet the extreme precision standards demanded by the aerospace sector.

- Composite Material Handling: Robots can weave carbon fiber layers without manual inconsistencies.

These examples underscore how diverse sectors rely on automated manufacturing not just for volume production but also for consistency, safety, and scalability.

8. Overcoming Common Challenges

While the potential benefits are enormous, the journey toward automated manufacturing isn’t without hurdles. Being aware of common pitfalls can help you plan more effectively:

8.1 High Initial Capital Investment

- Challenge: Purchasing robotics, sensors, and integration software can be expensive.

- Solution: Start with pilot projects. Many businesses lease or finance equipment to spread costs over time.

8.2 Workforce Upskilling

- Challenge: Automation changes job roles. Workers may fear job loss or struggle with advanced technologies.

- Solution: Invest in training programs. Encourage employees to handle oversight, programming, and maintenance of automated systems.

8.3 System Complexity

- Challenge: Integrating multiple technologies—like IoT, AI, and robotics—can lead to compatibility issues.

- Solution: Use standardized protocols (e.g., OPC UA) and partner with experienced system integrators.

8.4 Cybersecurity Risks

- Challenge: Increased connectivity opens the door to potential cyberattacks or data breaches.

- Solution: Implement robust firewalls, encryption, and real-time security monitoring.

8.5 Resistance to Change

- Challenge: Organizational inertia or fear of the unknown can stall automation projects.

- Solution: Demonstrate ROI through pilot programs and communicate the long-term vision to stakeholders.

By acknowledging these challenges early, you’ll be better equipped to form strategies that keep your automation journey on track.

9. Myths and Misconceptions

Automation is often misunderstood. Let’s clear up some of the biggest myths surrounding automated manufacturing:

- Myth: Automation Will Replace All Human Jobs

- Reality: While certain roles become automated, new positions emerge in system oversight, programming, and maintenance.

- Myth: Only Large Corporations Benefit

- Reality: Even small to mid-sized businesses can leverage collaborative robots or cloud-based solutions cost-effectively.

- Myth: Automation Only Involves Robots

- Reality: Automated manufacturing includes a broad spectrum—software-based process control, AI analytics, IoT sensors, and more.

- Myth: Automation Makes Work Environments Cold and Impersonal

- Reality: Human oversight remains essential. In many cases, automation frees staff from repetitive tasks, allowing them to focus on creative or strategic work.

- Myth: Automated Systems Never Fail

- Reality: Breakdowns and errors still occur, just with lower frequency. Effective maintenance and real-time monitoring are key to minimizing downtime.

Understanding and dispelling these myths is crucial for successfully adopting an automation strategy that aligns with both business goals and workforce well-being.

10. ROI and Cost Analysis

For many organizations, the decision to invest in automated manufacturing hinges on a solid return on investment (ROI). Before taking the plunge, consider these factors:

10.1 Initial Setup Costs

- Equipment and Hardware: Robotic arms, CNC machines, sensors, and safety enclosures.

- Software Licenses: AI platforms, MES, ERP modules, and integration tools.

10.2 Operational Savings

- Reduced Labor Costs: Fewer manual tasks mean you can either reallocate labor or reduce overtime.

- Lower Error Rates: Minimizing defective products cuts material wastage and rework costs.

10.3 Productivity Gains

- Faster Throughput: 24/7 operation significantly ups production volumes.

- Consistent Quality: Fewer defects also boost customer satisfaction and reduce returns.

10.4 Long-Term Value

- Scalability: As demand grows, an automated line can often scale with minimal downtime.

- Data-Driven Decisions: Real-time analytics inform continuous improvements, refining ROI over time.

In many cases, companies recoup automation investments within 2-5 years. Factors like product complexity, market volatility, and the pace of technological advancement can affect these timelines. However, considering the long-term competitive edge, automation often proves a wise investment.

11. Step-by-Step Implementation Strategy

Thinking of adopting or upgrading automated manufacturing in your facility? Here’s a structured roadmap to guide you:

- Assess Current Processes

- Identify bottlenecks, repetitive tasks, and error-prone areas.

- Gather input from production managers and frontline workers.

- Set Clear Objectives

- Are you aiming to boost throughput, improve quality, or reduce labor costs?

- Define Key Performance Indicators (KPIs) such as cycle time, defect rate, and energy usage.

- Choose the Right Technology

- Hardware Selection: Robot arms vs. cobots vs. CNC machines—match technology to your production needs.

- Software Integration: Ensure your MES, ERP, and AI tools can communicate seamlessly.

- Pilot Project

- Test a small-scale automation solution.

- Evaluate ROI, gather feedback, and refine your approach.

- Scale Up

- Roll out automation to larger sections of the production line.

- Provide continuous training to staff for smooth adoption.

- Monitor and Optimize

- Use IoT sensors and real-time analytics for ongoing performance checks.

- Tweak parameters, schedule predictive maintenance, and address issues quickly.

- Continuous Improvement

- Automation isn’t a “set it and forget it” endeavor.

- Regularly review KPIs, incorporate technological updates, and stay agile to new market demands.

By following these steps, you’ll minimize risks, foster employee buy-in, and set a sturdy foundation for scalable growth.

12. Future Trends Shaping Automated Manufacturing

Automation is not static; it’s a continuously evolving field influenced by emerging technologies and market demands. Here’s a glimpse into what the future may hold:

12.1 Hyper-Personalization

- Trend: Consumers increasingly demand custom products—think bespoke footwear or tailored medical devices.

- Impact: Flexible and additive manufacturing systems will become the gold standard.

12.2 Sustainable Automation

- Trend: Greater emphasis on reducing carbon footprints and waste.

- Impact: Energy-efficient robots, closed-loop water systems, and smart resource management will be built into automated lines.

12.3 AI-Driven Decision Making

- Trend: Machines learn and adapt in real-time, optimizing production without manual oversight.

- Impact: “Lights-out” factories where humans only intervene for system upgrades or strategic decisions.

12.4 Human-Robot Collaboration

- Trend: Cobots and exoskeletons will handle physically demanding tasks, while humans focus on problem-solving and creative tasks.

- Impact: Workplace ergonomics improve, labor shortages become less critical, and productivity skyrockets.

12.5 Blockchain and Enhanced Traceability

- Trend: End-to-end supply chain transparency.

- Impact: Every product’s journey from raw material to finished item is verified, improving trust and reducing counterfeits.

Keeping an eye on these trends will help you anticipate market shifts and ensure your automation investments remain relevant.

13. Frequently Asked Questions (FAQ)

- What is automated manufacturing?

Automated manufacturing is the use of technology—robots, AI, and software systems—to perform production tasks with minimal human intervention, aiming to increase efficiency and quality. - Is automated manufacturing only for large industries?

Not at all. Small to mid-sized companies can adopt collaborative robots or cloud-based solutions, making automation accessible at various scales. - How long does it take to see ROI on automation?

ROI timelines vary but typically range between 2-5 years, depending on factors like production volume, product complexity, and technology costs. - Will automation replace human jobs entirely?

While some manual roles may be reduced, new positions in programming, oversight, and maintenance often emerge. Automation generally shifts the workforce focus to higher-value tasks. - What are the biggest hurdles to implementing automation?

Common challenges include high upfront costs, workforce upskilling, and system complexity. However, pilot projects and strategic planning can mitigate these issues.

14. Useful Resources

Below are some authoritative resources to deepen your understanding and support fact-based decisions:

- International Federation of Robotics (IFR): Offers global statistics and reports on robotic adoption.

- MIT Manufacturing Research: Insights into cutting-edge manufacturing innovations.

- U.S. Department of Commerce – Manufacturing Sector: Access data and funding opportunities for manufacturers in the United States.

- World Economic Forum – Advanced Manufacturing: High-level discussions and whitepapers on Industry 4.0 and global trends.

Conclusion

Automated manufacturing isn’t just a buzzword—it’s a transformative strategy that can elevate your production lines, boost product quality, and keep your operations relevant in an ever-competitive marketplace. By harnessing the synergy of robotics, AI, IoT, and data analytics, companies can unlock efficiency gains that were once unimaginable.

However, successful automation requires more than just technology; it demands a people-centered approach, careful planning, and a commitment to continuous improvement. Whether you’re a small business owner eyeing your first collaborative robot or a multinational corporation expanding a fully automated facility, the key is to align your automation goals with clear metrics and long-term strategies.

What’s your next move?

- Have thoughts or questions about automated manufacturing? Share your insights or inquiries in the comments below.

- Ready to take the plunge? Explore our Automation Solutions Guide for even more advanced tips and step-by-step roadmaps.

- Want the latest updates? Subscribe to our newsletter and stay ahead of the curve with cutting-edge manufacturing insights!

Remember: Real success with automated manufacturing comes from merging human ingenuity with machine efficiency. Embrace the journey, stay informed, and watch your productivity soar.