The Ultimate Guide to Cartesian (Linear) Robots: Applications, Benefits, and Selection Guide

Have you ever watched a 3D printer meticulously create an object layer by layer, moving with precise coordination along three axes? Or seen automated pick-and-place machines in factories rapidly sorting products with incredible accuracy? These are Cartesian robots in action, quietly revolutionizing manufacturing and automation across industries worldwide.

Also known as linear robots or gantry robots, Cartesian robots are among the most widely deployed automation solutions today—yet many professionals still struggle to understand their full capabilities, applications, and selection criteria. Whether you’re an engineer considering automation options, a manufacturing manager looking to improve efficiency, or simply curious about industrial robotics, this comprehensive guide will walk you through everything you need to know about these remarkable machines.

Table of Contents

What Are Cartesian (Linear) Robots?

Cartesian robots derive their name from the Cartesian coordinate system developed by French mathematician René Descartes. These robots move linearly along the three perpendicular axes (X, Y, and Z) that define three-dimensional space. Unlike their articulated robot cousins that use rotational joints, Cartesian robots employ prismatic (sliding) joints to achieve precise linear movement.

The fundamental structure consists of:

- X-axis: Horizontal movement (left/right)

- Y-axis: Horizontal movement (forward/backward)

- Z-axis: Vertical movement (up/down)

- End effector: The tool or gripper mounted at the end

This seemingly simple design belies the incredible versatility and precision these robots bring to industrial applications. With positioning accuracy often measured in micrometers, Cartesian robots excel in tasks where repeatability and spatial precision are non-negotiable requirements.

The Evolution of Cartesian Robotics

The journey of Cartesian robots began in the early days of industrial automation, but their sophistication has increased dramatically over the decades.

Early Beginnings

The first Cartesian systems emerged in the 1950s and 1960s as rudimentary mechanical positioning devices. These early linear motion systems were primarily used for simple pick-and-place operations and basic material handling tasks. Their control systems were limited, often relying on mechanical stops or basic electrical limit switches.

Digital Transformation

The introduction of programmable logic controllers (PLCs) and computer numerical control (CNC) in the 1970s and 1980s revolutionized Cartesian robotics. Suddenly, these machines could be programmed for complex motion sequences, with improved accuracy and repeatability.

Modern Advancements

Today’s Cartesian robots leverage sophisticated technologies:

- High-resolution encoders for position feedback

- Advanced servo motor control for smooth motion profiles

- Complex kinematics calculations performed in real-time

- Integration with machine vision and AI systems

- Network connectivity for Industry 4.0 applications

This evolution has transformed Cartesian robots from simple mechanical devices into intelligent automation tools capable of adapting to changing production requirements and working alongside human operators in collaborative environments.

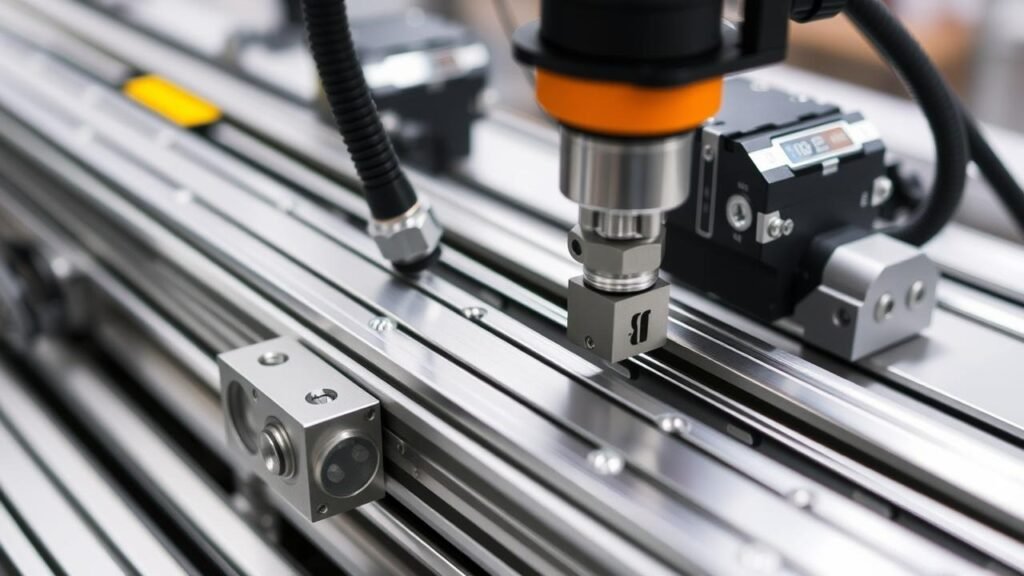

Key Components of Cartesian Robot Systems

Understanding the anatomy of a Cartesian robot helps in appreciating its capabilities and selecting the right configuration for specific applications.

Structural Framework

The backbone of any Cartesian system is its framework, which must be rigid enough to maintain precision while supporting the required payload. Materials range from aluminum extrusions for lighter applications to steel frames for heavy-duty industrial use. The framework’s design fundamentally influences the robot’s workspace, load capacity, and overall performance.

Linear Actuators

Each axis requires a linear actuator to convert rotational motion from motors into linear movement. Common actuator types include:

- Ball screws: Offer high precision and moderate speed, excellent for applications requiring positional accuracy

- Belt drives: Provide higher speeds but slightly less precision, ideal for longer travel distances

- Linear motors: Deliver the highest speed and acceleration with excellent precision, though at higher cost

Drive Systems

The drive system powers the robot’s movement and typically consists of:

- Motors: Usually servo motors or stepper motors, with servo motors offering higher performance at increased cost

- Controllers: The “brain” of the system that coordinates motion across all axes

- Feedback devices: Encoders that monitor position and velocity to ensure accuracy

End Effectors

The end effector is the business end of the robot—the tool that interacts with workpieces or the environment. Common end effectors include:

- Vacuum grippers for handling flat or lightweight objects

- Mechanical grippers for securing items with different geometries

- Process tools like dispensing nozzles, welding heads, or cutting tools

- Inspection instruments such as cameras or sensors

The modularity of Cartesian robots allows for quick interchange of end effectors, making these systems highly adaptable to changing production requirements.

Applications Across Industries

The versatility of Cartesian robots has led to their adoption across numerous industries and applications.

Manufacturing and Assembly

In manufacturing environments, Cartesian robots excel at:

- Pick and place operations: Transferring components between workstations or placing parts into assemblies

- Precision assembly: Inserting electronic components into circuit boards or assembling small mechanical devices

- Material handling: Moving raw materials or finished products along production lines

- Packaging: Loading products into boxes or arranging items in specific patterns

Laboratory and Medical Applications

The precision of Cartesian systems makes them ideal for laboratory work:

- Liquid handling: Precise dispensing and sampling in diagnostic equipment

- Test automation: Moving test probes or instruments in quality control applications

- Medical device manufacturing: Assembling sensitive medical components with high precision

- Pharmaceutical processing: Handling delicate vials or test tubes in automated screening processes

3D Printing and Additive Manufacturing

The familiar movement of 3D printer heads follows Cartesian principles:

- Fused deposition modeling (FDM): Positioning the print head to deposit material layer by layer

- Selective laser sintering: Positioning lasers that fuse powdered materials

- Bio-printing: Precise placement of biological materials for tissue engineering

Electronics Manufacturing

The electronics industry relies heavily on Cartesian automation:

- PCB population: Placing components on circuit boards

- Wire bonding: Creating electrical connections between components

- Testing and inspection: Moving probes or cameras to verify assembly quality

- Dispensing: Applying adhesives, thermal compounds, or conformal coatings

Food Processing

Even food production benefits from Cartesian robotics:

- Food sorting: Separating items by size, shape, or quality

- Decorating: Precisely applying decorative elements to baked goods

- Packaging: Arranging products in specific patterns or containers

- Portion control: Dispensing exact amounts of ingredients

Benefits of Implementing Cartesian Robot Systems

The widespread adoption of Cartesian robots stems from their numerous advantages over both manual processes and other automation solutions.

Unmatched Precision and Repeatability

Cartesian robots achieve positioning accuracies of ±0.01mm or better, with some high-end systems reaching micrometer-level precision. This exceptional accuracy translates to:

- Consistent product quality

- Reduced defect rates

- Ability to handle increasingly miniaturized components

- Reliable performance of delicate operations

Customizable Workspace

Unlike articulated robots with fixed reach limitations, Cartesian systems can be designed with virtually any workspace dimensions. This flexibility allows:

- Customization to fit existing facility layouts

- Scalability as production requirements change

- Optimization of floor space utilization

- Adaptation to various product sizes

Cost-Effectiveness

For many applications, Cartesian robots offer the best value proposition:

- Lower initial investment compared to six-axis robots for similar workspace coverage

- Simplified programming reduces implementation costs

- Standardized components facilitate maintenance and repairs

- Modular design allows for gradual expansion

Programming Simplicity

The intuitive coordinate system makes Cartesian robots more straightforward to program:

- Direct correlation between programming coordinates and physical space

- Simpler kinematics calculations reduce processing requirements

- Easier integration with existing production software

- Lower training requirements for operators and programmers

Reliability and Longevity

With fewer moving parts than articulated robots, Cartesian systems typically offer:

- Extended service life

- Reduced maintenance requirements

- Higher mean time between failures (MTBF)

- Lower total cost of ownership

Limitations to Consider

Despite their many advantages, Cartesian robots aren’t the perfect solution for every application.

Speed Constraints

Due to their linear motion mechanisms, Cartesian robots typically can’t match the speed of delta robots or SCARA robots in certain applications. The need to move substantial mass along each axis can limit acceleration capabilities, particularly in larger systems.

Space Requirements

The footprint of a Cartesian robot must encompass its entire working envelope, which can consume significant floor space for large-scale applications. Unlike articulated robots that can fold their arms to conserve space, Cartesian systems require permanent clearance throughout their range of motion.

Limited Flexibility for Complex Paths

While excellent for straight-line movements, Cartesian robots lack the rotational capabilities of six-axis robots. This limitation makes them less suitable for tasks requiring complex three-dimensional paths or orientation changes, such as spray painting contoured surfaces or welding complex geometries.

Structural Considerations

Larger Cartesian systems may require substantial supporting structures, especially when overhead gantry configurations are employed. These structural requirements can add to installation costs and complexity.

Selecting the Right Cartesian Robot for Your Application

Choosing the optimal Cartesian robot configuration involves evaluating several critical factors.

Payload Requirements

The weight of objects the robot will handle directly impacts component selection:

- Light payloads (< 5 kg): Aluminum profiles and belt drives often suffice

- Medium payloads (5-50 kg): May require steel reinforcement and ball screws

- Heavy payloads (> 50 kg): Need robust structural components and possibly multiple drive systems

Always factor in not just the weight of the product but also the end effector and any acceleration forces during operation.

Speed and Acceleration Needs

Application cycle time requirements determine the necessary speed capabilities:

- High-speed pick-and-place operations might need belt drives or linear motors

- Precision assembly can utilize slower ball screw systems

- Consider the impact of acceleration and deceleration on system wear and precision

Precision and Repeatability Requirements

Different applications demand different levels of accuracy:

- Standard automation: ±0.1mm is often sufficient

- Electronics assembly: May require ±0.01mm or better

- Micromanipulation: Could need sub-micron precision

Remember that positioning accuracy and repeatability are different specifications—both matter for overall system performance.

Environmental Considerations

The operating environment significantly impacts component selection:

- Clean rooms require special materials and lubricants

- Washdown environments need sealed components and corrosion-resistant materials

- High-temperature applications may require special cooling systems

- Dusty environments need appropriate sealing and filtration

Integration Requirements

Consider how the robot will connect with other systems:

- What controller platform will be used?

- What communication protocols are needed?

- Will vision systems be integrated?

- How will safety systems interface with the robot?

Budget Constraints

Cost optimization strategies include:

- Selecting appropriate components without overengineering

- Considering modular, standardized systems vs. custom designs

- Evaluating the total cost of ownership, not just initial investment

- Phased implementation for large-scale projects

Implementation Best Practices

Successfully deploying Cartesian robots requires careful planning and execution.

System Design and Simulation

Before physical assembly, thoroughly model the system:

- Use simulation software to verify workspace coverage

- Analyze motion profiles for potential collisions or interferences

- Optimize cycle times through virtual commissioning

- Verify that performance requirements will be met

Installation Considerations

Proper installation is critical for system performance:

- Ensure the mounting surface is level and rigid

- Follow alignment procedures meticulously

- Verify orthogonality between axes

- Properly tension belts and align ball screws

- Implement appropriate cable management systems

Programming Approaches

Modern Cartesian robots offer multiple programming methods:

- Teach pendant programming: Simple point-to-point programming using a handheld device

- Offline programming: Creating motion sequences in simulation software before deploying to the physical system

- Text-based programming: Writing code directly in languages like G-code, ladder logic, or proprietary robot languages

- Graphical programming: Using flowchart-like interfaces to create motion sequences

Choose the approach that best matches your team’s skills and the application complexity.

Safety Implementation

Robotics safety should never be an afterthought:

- Conduct thorough risk assessments

- Implement appropriate guarding or safety sensors

- Follow relevant safety standards (ISO 10218, ANSI RIA R15.06)

- Train operators and maintenance personnel properly

- Establish clear emergency procedures

Future Trends in Cartesian Robotics

The field of Cartesian robotics continues to evolve with several exciting developments on the horizon.

Collaborative Cartesian Systems

While collaborative robots (cobots) are typically associated with articulated arms, collaborative Cartesian systems are emerging with:

- Force-sensing capabilities for detecting human contact

- Safety-rated monitored stop functions

- Reduced speed operation when humans are present

- Integration with advanced safety sensing systems

These developments are making Cartesian robots suitable for human-robot collaborative workspaces.

AI and Machine Learning Integration

Artificial intelligence is enhancing Cartesian robot capabilities:

- Adaptive motion planning based on part variations

- Self-optimization of motion profiles for efficiency

- Predictive maintenance using operational data

- Automatic adjustment to environmental changes

IoT and Industry 4.0 Connectivity

Modern Cartesian systems are becoming integral parts of connected factories:

- Real-time performance monitoring and data collection

- Remote diagnostics and troubleshooting

- Integration with manufacturing execution systems (MES)

- Participation in facility-wide optimization strategies

Miniaturization for Precision Applications

As technology demands ever-smaller components, Cartesian robots are scaling down:

- Micro-scale positioning systems for semiconductor manufacturing

- Ultra-precise systems for optical component assembly

- Miniaturized medical and laboratory automation

Common FAQs About Cartesian Robots

How do Cartesian robots compare to SCARA and 6-axis robots?

Cartesian robots excel in applications requiring linear motion across a rectangular workspace with high precision. They’re typically more straightforward to program and often more cost-effective for their workspace volume. SCARA robots offer excellent speed for pick-and-place operations in a cylindrical workspace, while 6-axis robots provide maximum flexibility for complex motion paths and orientation changes. The best choice depends on your specific application requirements.

What maintenance do Cartesian robots require?

Typical maintenance includes:

- Regular lubrication of linear guides and ball screws

- Belt tension checks and adjustments

- Bearing inspections

- Cable and hose management system checks

- Control system updates and backups

- Calibration verification

Preventative maintenance schedules vary by usage intensity and environment but typically range from monthly to quarterly inspections.

Can Cartesian robots work with vision systems?

Absolutely! Integration with vision systems is common and enhances capabilities by allowing:

- Part location identification regardless of orientation

- Quality inspection during handling

- Sorting based on visual characteristics

- Adaptive picking from randomly arranged parts

- Verification of assembly completion

Modern controllers often include built-in vision system interfaces to simplify this integration.

What’s the typical return on investment (ROI) period?

ROI periods vary widely based on application and implementation, but many Cartesian robot deployments achieve payback within 12-24 months through:

- Labor savings

- Quality improvements

- Increased throughput

- Reduced material waste

- Enhanced production flexibility

Applications with high precision requirements, hazardous conditions, or 24/7 operation often see the fastest returns.

How difficult is it to repurpose a Cartesian robot for new applications?

One of the significant advantages of Cartesian systems is their adaptability. Repurposing typically involves:

- Changing the end effector for different tasks

- Updating programming for new motion sequences

- Potential adjustments to speed and acceleration parameters

- Software reconfiguration for new tasks

The modular nature of these systems makes them excellent candidates for redeployment as production needs evolve.

Conclusion: The Enduring Value of Cartesian Automation

Despite the emergence of new robotics technologies, Cartesian robots maintain their position as workhorses of industrial automation. Their blend of precision, reliability, and adaptability makes them ideal solutions for countless applications across diverse industries.

As manufacturing continues to evolve toward greater flexibility and connectivity, Cartesian systems are adapting with enhanced capabilities, intelligence, and integration options. Whether you’re automating a simple pick-and-place operation or developing a complex multi-stage production process, Cartesian robots offer a proven foundation for success.

The key to maximizing their potential lies in proper selection, implementation, and ongoing optimization—ensuring these versatile machines continue delivering value throughout their operational life.

What Cartesian robot applications are you considering for your operations? Have you already implemented these systems and have insights to share? We’d love to hear about your experiences and questions in the comments below!

This comprehensive guide was developed by automation experts with decades of combined experience in designing, implementing, and optimizing Cartesian robot systems across manufacturing, electronics, medical, and food processing industries. For personalized guidance on your specific automation needs, contact our engineering team today.