Unleashing the Power of Factory Automation: Your Ultimate Guide to Streamlined, Smart Manufacturing

Have you ever wondered how the world’s leading manufacturers reduce costs, maximize efficiency, and deliver top-notch products at lightning speed? The answer often lies in a powerful concept known as factory automation. From high-speed assembly robots to predictive analytics that minimize downtime, factory automation has become the backbone of modern, competitive manufacturing. If you’re aiming to scale your production capacity, improve product quality, or simply stay ahead of competitors, this comprehensive guide will be your roadmap.

In the next several sections, you’ll learn how factory automation works, why it’s vital for modern businesses, and how you can implement it successfully. By the end, you’ll have a clear picture of how to harness automation’s transformative power—no fluff, no empty promises, just real insights, expert-backed tips, and strategies that deliver results. Let’s dive in.

Table of Contents

1. Understanding the Essence of Factory Automation

Factory automation is the systematic use of technology—such as robotics, control systems, and data analytics tools—to operate and monitor manufacturing processes with minimal human intervention. It’s not about entirely replacing human labor; rather, it’s about enhancing human capabilities, streamlining repetitive tasks, and removing inefficiencies.

1.1 The Historical Evolution of Automation

- Early Mechanization (Late 18th Century): The Industrial Revolution introduced steam engines, mechanized looms, and simple conveyor systems.

- The Assembly Line (Early 20th Century): Henry Ford famously integrated moving assembly lines to mass-produce automobiles, cutting costs and improving throughput.

- Computerized Controls (Mid-20th Century): Programmable Logic Controllers (PLCs) and CNC machines began automating tasks like machining and product assembly.

- Full-Scale Robotic Automation (Late 20th Century – Present): Robots started to handle tasks previously done by humans—welding, painting, and heavy lifting, among others.

- Industry 4.0 & Smart Factories (21st Century): Connectivity, data analytics, and machine learning took automation to a new level, enabling fully integrated and predictive production environments.

1.2 Types of Factory Automation

- Fixed Automation: Systems designed for a single, high-volume product (e.g., a dedicated assembly line for one automotive part).

- Programmable Automation: Machinery that can be reconfigured for different tasks, yet still requires manual setup changes (e.g., CNC machines).

- Flexible Automation: Highly adaptable systems that can switch between product types with minimal retooling (e.g., robotics that reprogram themselves via advanced software).

Each type serves specific needs. For instance, fixed automation works best for extremely high-volume, standardized manufacturing. Flexible automation thrives in environments where product variations are frequent, reducing downtime and costs associated with changing setups.

2. Why Factory Automation Matters in the Modern Marketplace

In today’s hyper-competitive environment, you can’t afford inefficiencies. Even minor production bottlenecks or quality issues can give your competitors an edge. Here’s why factory automation has become a strategic imperative:

2.1 Competitive Advantage

Automation boosts production speed and consistency while minimizing errors. According to a McKinsey Global Institute report, companies that adopt automation effectively can reduce production times by up to 40% and cut manufacturing costs by 15–25%. This translates directly to competitive pricing and faster time-to-market.

2.2 Labor Efficiency and Upskilling

Contrary to popular myths, automation doesn’t always replace people—it often redefines their roles. Freed from monotonous tasks, workers can focus on higher-value activities like quality control, process optimization, and R&D. The demand for skilled operators who can manage automated systems has grown, leading to upskilling opportunities.

2.3 Improved Quality and Consistency

Automated systems excel at performing the same task thousands—or even millions—of times without variance. This level of consistency is crucial in sectors like automotive, aerospace, and medical devices, where small deviations can have massive repercussions.

2.4 Scalability

When demand spikes, automated factories can adapt more quickly than traditional setups. You can ramp production up or down relatively easily, especially if you have flexible automation systems in place. This scalability makes your operations more resilient to market fluctuations.

3. Core Components of a Fully Automated Factory

Implementing factory automation involves an ecosystem of technologies and practices. Below are some of the critical elements you’ll encounter:

3.1 Industrial Robots

Robots come in various forms—articulated arms, cartesian systems, SCARA robots, and more. Each style suits different tasks like welding, assembly, painting, or picking and placing items. Leading robotics manufacturers, such as ABB, FANUC, and KUKA, continually innovate in areas like collaborative robots (cobots), which can safely work alongside humans.

3.2 Programmable Logic Controllers (PLCs)

PLCs are the “brains” behind automated machinery, controlling everything from conveyor speed to robotic arm movements. They are built to withstand harsh industrial environments (temperature extremes, dust, humidity) and can be reprogrammed to accommodate new workflows.

3.3 Sensor Networks

Sensors measure temperature, pressure, vibration, and more, offering real-time data to control systems. In a modern factory, sensors are crucial for quality assurance, predictive maintenance, and process optimization. For example, an IoT-enabled sensor can detect tiny changes in vibration patterns that signal a machine’s impending failure.

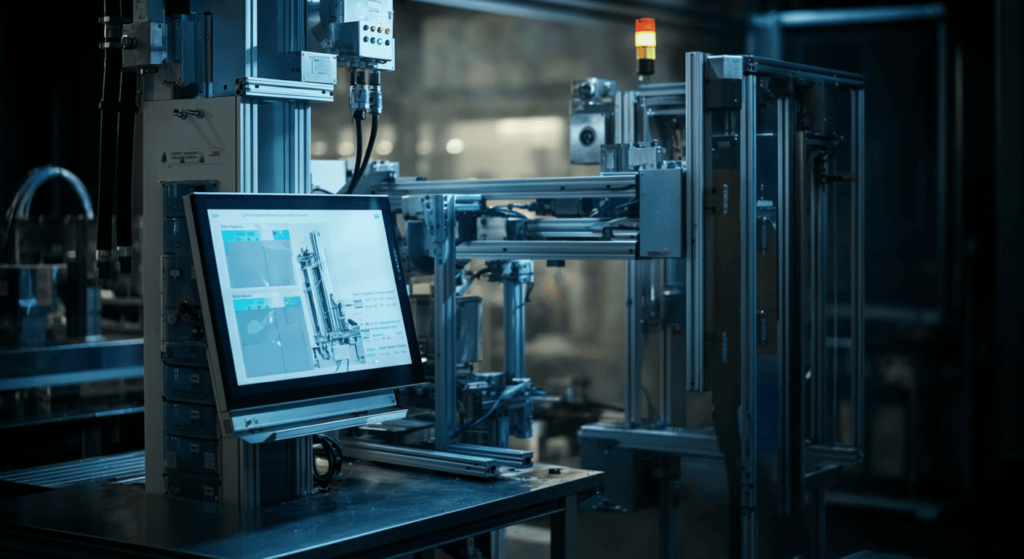

3.4 Human-Machine Interfaces (HMIs)

These are screens or dashboards operators use to monitor and interact with automated systems. A well-designed HMI empowers workers to control equipment, visualize data, and respond to alarms or system updates in real time.

3.5 Data Analytics and Cloud Integration

Data analytics platforms aggregate machine data, production metrics, and supply chain info for actionable insights. Cloud-based solutions enable global teams to access real-time production data and performance dashboards from anywhere.

3.6 Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs)

AGVs and AMRs transport materials within a facility without human drivers. They navigate using tracks, lasers, or vision systems, reducing manual labor and optimizing workflow. In some advanced operations, these mobile robots can coordinate with robotic arms to form a fully automated supply chain.

4. Key Benefits and ROI of Factory Automation

Before investing significant capital and manpower in automation, you need to understand the potential gains. While exact ROI varies by industry, typical benefits include:

- Increased Throughput: Automated lines can run continuously with fewer errors, boosting productivity.

- Reduced Waste and Scrap Rates: Consistent machine operations reduce errors and material waste.

- Lower Labor Costs: Automation can reduce the need for manual labor in repetitive tasks while freeing employees to tackle higher-level responsibilities.

- Enhanced Safety: Robots can handle dangerous tasks, thereby reducing workplace injuries.

- Better Data Visibility: Automated systems produce a wealth of data that can be analyzed for continuous improvement.

According to a Deloitte study, 79% of manufacturers implementing widespread automation reported increased profitability within the first 12 months, underscoring just how tangible these benefits can be.

5. Industry 4.0 and the Role of Data-Driven Manufacturing

It’s hard to discuss factory automation today without touching on Industry 4.0—the digitization and interconnectivity revolution. Let’s break down how it fits in:

5.1 The Pillars of Industry 4.0

- Interconnectivity: Machines, devices, sensors, and people communicate seamlessly (IoT).

- Information Transparency: Data from the production floor feeds into centralized systems for analysis.

- Technical Assistance: Systems provide real-time insights and even predictive suggestions to human operators.

- Decentralized Decisions: Machines can make certain decisions on their own (e.g., self-adjusting production parameters based on sensor data).

5.2 Big Data and Predictive Analytics

Modern factories generate terabytes of data each day. The key lies in turning that data into actionable insights. For instance, predictive maintenance algorithms can foretell machine failures before they happen, saving companies an average of 12% on maintenance costs while reducing downtime by 70%, according to the U.S. Department of Energy.

5.3 Cyber-Physical Systems (CPS)

These are systems where physical machines are deeply integrated with computer networks. Think of a robot arm that not only performs assembly but also adjusts its parameters based on real-time feedback from AI algorithms in the cloud.

5.4 Enhanced Supply Chain Visibility

Data-driven factories are not isolated entities. They often share data with suppliers and logistics partners, allowing for just-in-time delivery, minimized inventory, and rapid response to market demand changes.

6. Essential Steps to Plan a Successful Automation Strategy

Automation isn’t just about buying a few robots and hoping for the best. A strategic approach ensures you maximize ROI and avoid pitfalls.

6.1 Define Clear Objectives

Start by answering foundational questions:

- What processes are most time-consuming or error-prone?

- Are you seeking to increase capacity or improve quality?

- How will automation align with your broader business goals?

6.2 Conduct a Workflow Analysis

Map out current processes in detail. Identify bottlenecks, repetitive tasks, and critical points where errors occur. This blueprint helps you pinpoint areas with the highest potential for improvement.

6.3 Financial Planning and ROI Forecasting

Automation requires upfront investment, from purchasing equipment to retraining staff. Conduct a cost-benefit analysis:

- Capital Expenditures (CapEx): Robots, conveyors, software licenses, system integration fees.

- Operational Expenditures (OpEx): Maintenance, electricity, software updates.

- ROI Timeline: Most well-planned automation projects recoup costs within 2–5 years.

6.4 Choose the Right Technology Partners

Don’t just compare prices; look for partners with proven industry experience, robust after-sales support, and the flexibility to adapt solutions to your needs.

6.5 Implement Pilot Projects

Begin with a smaller, controlled pilot project to test the feasibility. Measure results rigorously, gather feedback, and refine processes before scaling up.

6.6 Training and Change Management

Automation can be a cultural shift. Communicate openly with employees, provide training on new systems, and involve them in the transition to minimize resistance.

6.7 Continuous Improvement Loop

After deployment, monitor performance metrics (throughput, downtime, quality levels) and seek incremental gains. Stay updated on evolving automation trends and technologies to remain competitive.

7. Real-World Examples and Case Studies

Sometimes the best way to understand factory automation’s power is to see it in action. Below are some brief but illuminating examples.

7.1 Automotive Assembly Lines

Leading car manufacturers like Toyota and Ford rely on highly automated assembly lines. Robots weld car frames, apply paint coatings, and place seats with near-perfect consistency. According to Toyota, automation has cut welding defects by 50% while doubling production capacity in some plants.

7.2 Electronics Manufacturing

Circuit boards and consumer electronics often require extreme precision. Automation allows for rapid component placement at micron-level accuracy. Global electronics giants (e.g., Foxconn) utilize automated lines to assemble smartphones, tablets, and wearables, reducing human error and accelerating production cycles.

7.3 Food and Beverage Industry

Take a chocolate factory, for example. Automated systems monitor temperatures during melting, mixing, and molding to maintain consistency. Automated packaging lines wrap chocolates at speeds no human could match. The result? Higher throughput and standardized quality.

7.4 Pharmaceuticals

Pharmaceutical companies must adhere to stringent regulatory standards. Automated systems ensure sterile conditions, measure exact doses, and track products through serialization, significantly lowering the risk of cross-contamination or dosage errors.

7.5 Logistics and Warehousing

E-commerce giants like Amazon heavily automate fulfillment centers. Robots pick items from shelves, move them to packaging stations, and even sort boxes for shipping. This level of automation reduces order processing time from hours to minutes.

8. Common Misconceptions About Factory Automation

Despite the clear benefits, factory automation is often misunderstood. Let’s dispel a few myths:

- “Automation kills all human jobs.”

While some manual roles may decrease, automation generally shifts roles rather than eliminates them outright. Skilled operators, data analysts, and maintenance technicians are in higher demand than ever. - “It’s only for large corporations.”

Thanks to rapidly falling hardware costs and scalable software solutions, even small and medium-sized manufacturers can benefit from automation. - “Automation is a one-and-done process.”

In reality, it’s an ongoing journey. Technology evolves, and so do market demands. Continuous improvement is essential. - “Automation always requires cutting-edge robotics.”

Sometimes, simpler solutions—like basic conveyor systems or partial machine upgrades—can yield significant gains without huge investment. - “Quality control is fully automated.”

While automated vision systems help detect defects, human oversight remains critical, especially in nuanced tasks like final inspections or custom finishing work.

9. Frequently Asked Questions (FAQ)

Below are some of the most common questions manufacturers and business owners have about factory automation:

9.1 Is factory automation only suitable for large manufacturers?

No. While large corporations have historically led the way, small and medium enterprises (SMEs) can increasingly afford automation. Scalable solutions, collaborative robots, and cloud-based platforms allow smaller operations to invest in automation at lower costs and expand gradually.

9.2 Does automation eliminate human jobs entirely?

Not entirely. Most often, it changes the nature of jobs. Repetitive or hazardous tasks become automated, and humans shift to roles requiring critical thinking, process oversight, and innovation. Many companies report reassigning workers to more strategic tasks once automation is introduced.

9.3 What does it cost to automate a production line?

Costs vary widely based on the scope of automation, choice of technology, and industry-specific requirements. A simple robotic arm might cost $50,000–$80,000, while an entire automated line can run into millions. Performing an ROI analysis helps clarify potential long-term gains versus initial capital outlays.

9.4 How does factory automation enhance product quality?

Automated systems consistently adhere to predefined parameters, reducing variation. This leads to fewer defects and higher uniformity in output. Many automated lines also incorporate advanced quality control sensors that catch anomalies in real time, thus preventing faulty products from reaching later production stages.

9.5 Is factory automation the same as Industry 4.0?

They’re closely related but not identical. Factory automation can exist independently of Industry 4.0 principles, focusing primarily on mechanizing tasks. Industry 4.0, on the other hand, emphasizes digital connectivity, data analytics, and smart systems that integrate with broader supply chains. You can implement factory automation without fully adopting Industry 4.0, but adopting both can yield the greatest benefits.

10. Internal & External Resource Links

Other Resources:

- International Federation of Robotics (IFR) – Industry data, statistics, and global trends on robotic automation.

- McKinsey & Company Manufacturing Insights – Leading research on how automation is reshaping the manufacturing landscape.

- U.S. Department of Energy – Manufacturing – Articles and case studies on energy-efficient automated manufacturing.

Conclusion

Factory automation is no longer a futuristic buzzword—it’s a present-day reality shaping every facet of modern manufacturing. From reducing operational costs and improving product quality to boosting overall competitiveness, automation has become indispensable. If you’re serious about scaling your operations, enhancing consistency, and future-proofing your business, there’s never been a better time to explore automation.

Keep in mind, factory automation works best when it aligns with your specific goals. Start by conducting a thorough workflow analysis, setting clear objectives, and creating a realistic roadmap. Partner with experienced vendors, involve your workforce through proper training, and embrace data-driven technologies to unlock the full potential of Industry 4.0.

What’s Your Take?

Ready to transform your facility into a fully automated powerhouse? Share your thoughts or experiences in the comments below. Have questions? Reach out, and let’s keep the conversation going!

Ready to discover more? For additional resources, check out our main website at Robotics Engineering and stay ahead of the automation curve!