Industrial Robotics: Transforming Global Manufacturing

Ever wondered how factory floors stay efficient around the clock, churning out products with near-flawless precision? The answer often lies in industrial robotics. Over the last few decades, industrial robots have reshaped the global manufacturing landscape—reducing costs, boosting productivity, and elevating product quality like never before. As technology continues to evolve, companies of all sizes are exploring ways to integrate robots into their production lines, driving innovation and placing themselves at the forefront of competitive markets.

In this comprehensive guide, we’ll take a deep dive into what industrial robotics truly entails, why it’s a game-changer in modern manufacturing, and how your business can tap into its benefits. From exploring the different types of robots to debunking common misconceptions, prepare to discover everything you need to know about this fascinating field. Let’s get started.

Table of Contents

1. The Evolution of Industrial Robotics

Industrial robotics, as we know it today, has roots stretching back to the mid-20th century. Here’s a quick tour through history:

- Early Beginnings (1950s–1960s): The first real “industrial robot” concept emerged in the 1950s, largely driven by the need to automate repetitive tasks in manufacturing. Companies like General Motors and Ford began experimenting with rudimentary robotic arms to handle dangerous or monotonous tasks on their assembly lines.

- Expansion in the 1970s: Robotics technology became more sophisticated with the introduction of electronic controls and better servo motors. Manufacturers started integrating robots for welding, painting, and material handling. During this period, the robotics market expanded significantly in response to labor shortages and the desire for higher productivity.

- Rise of Computerized Control (1980s–1990s): Advancements in microprocessors and control systems allowed robots to become more precise and flexible. Vision systems and programmable controls led to a surge in complex tasks previously impossible for basic robotic arms. Companies also began to see that robotics could ensure quality consistency on a mass scale.

- 21st Century Breakthroughs (2000s–Present): With the advent of sophisticated sensors, AI-driven software, and machine learning, modern industrial robots now excel at tasks requiring fine motor skills, adaptive decision-making, and real-time data processing. We see collaborative robots (cobots) working side by side with human operators, revolutionizing how we think about factory floors and production efficiency.

This evolution underscores one fundamental trend: as technology matures, industrial robotics becomes more powerful, flexible, and accessible. No longer confined to massive manufacturing complexes, robots are now within reach for mid-sized and even small enterprises.

2. What Are Industrial Robots?

An industrial robot is more than just a machine. It’s a programmable, automated system designed to perform various tasks—ranging from assembly, welding, and painting to material handling and packaging. These robots typically feature:

- Articulated Joints: Most industrial robots have multiple joints or axes, allowing for versatile movement similar to a human arm.

- Precise Control: Advanced sensors and control algorithms enable robots to execute tasks with pinpoint accuracy.

- Programmability: Whether it’s a repetitive operation or a complex sequence of actions, industrial robots can be programmed to perform it consistently.

- Adaptive Functions: Modern robotics systems often incorporate machine vision and AI to adapt to changes in their environment or process variables.

Industrial Robotics vs. Traditional Automation

The main differentiator between industrial robotics and older forms of automation (like fixed mechanical systems) is flexibility. Traditional automation setups are typically designed for one specific task. In contrast, industrial robots can be reprogrammed or equipped with different end effectors (like grippers, welding torches, or suction cups) to handle multiple tasks, making them more cost-effective and scalable in dynamic production environments.

3. Key Components of an Industrial Robot

Industrial robots may vary in shape, size, and complexity, but most share a few core components that make them tick:

- Manipulator (Arm): The “body” of the robot, responsible for movement. This arm usually has several axes or joints, enabling it to maneuver in three-dimensional space.

- End Effector (Tool): The specialized attachment that directly interacts with the workpiece—think grippers, welding torches, or spray nozzles.

- Controller: Often considered the “brain” of the robot, it interprets program instructions and sends the corresponding signals to the motors.

- Drive System (Actuators): This includes motors and mechanical transmission parts (gears, belts, chains) that move the robot’s joints.

- Sensors: Sensors feed the controller with essential data—like position, velocity, force, or even visual feedback for more advanced robots.

- Human-Machine Interface (HMI): A control panel or digital interface through which operators program and monitor the robot’s performance.

These elements work in unison to create a highly efficient system. In many cases, robotics also tie into broader factory-floor networks, using Industrial Internet of Things (IIoT) frameworks to communicate data in real time.

4. Common Types of Industrial Robots

The industrial robotics landscape includes several robot types, each suited to specific tasks. Below are some of the most common:

4.1 Articulated Robots

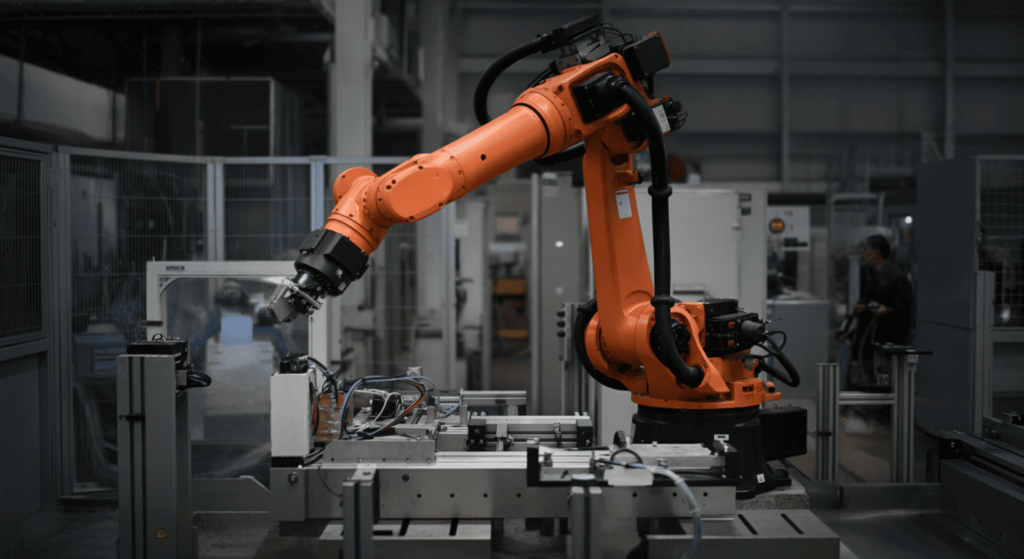

- Description: Resembling a human arm, these robots have rotary joints that can range from two to ten axes (though six is the most common).

- Typical Uses: Welding, material handling, assembly, painting.

- Advantages: Highly versatile, excellent range of motion, ideal for complex tasks.

4.2 SCARA Robots

- Description: SCARA stands for Selective Compliance Assembly Robot Arm. They excel in lateral movements but have limited vertical flexibility.

- Typical Uses: Pick-and-place tasks, small assembly tasks (like electronics).

- Advantages: Fast and precise for tasks that require moving objects between two horizontal planes.

4.3 Delta (Parallel) Robots

- Description: Known for their spider-like appearance, delta robots have three arms connected to universal joints at a common base.

- Typical Uses: High-speed pick-and-place operations, packaging, sorting.

- Advantages: Extremely fast, suitable for lightweight tasks requiring rapid movement.

4.4 Cartesian (Gantry) Robots

- Description: These move in straight lines along X, Y, and Z axes. Think of a 3D printer’s framework.

- Typical Uses: CNC machining, 3D printing, large-scale assembly.

- Advantages: Simple geometry, excellent for tasks requiring precision along orthogonal axes.

4.5 Collaborative Robots (Cobots)

- Description: Designed to work safely alongside humans, cobots are equipped with sensors to detect collisions and minimize risk.

- Typical Uses: Light assembly tasks, packaging, quality checks.

- Advantages: Enhanced safety features, user-friendly programming, smaller footprint.

By choosing the right type of robot, manufacturers can optimize cycle times, improve output quality, and reduce operating costs.

5. The Role of Industrial Robotics in Modern Manufacturing

Today’s manufacturing environment is defined by mass customization, just-in-time production, and rigorous quality standards. Industrial robotics plays a pivotal role by offering the scalability, consistency, and speed needed to meet these high demands.

- Mass Production & Consistency: Robots excel in repetitive tasks, ensuring consistent quality over thousands or even millions of cycles.

- Workforce Augmentation: Rather than replacing human labor entirely, robots often handle mundane or hazardous tasks, freeing people to focus on innovation and problem-solving.

- Cost Efficiency: While initial investments can be high, the long-term operational savings are substantial—reduced labor costs, fewer product defects, and increased throughput.

- Competitive Advantage: Early adopters of advanced automation can gain a strong foothold in their markets, outpacing competitors in productivity and innovation.

In a world driven by rapid demand shifts, industries must stay agile. Industrial robotics offers a proven strategy for businesses aiming to scale up or pivot quickly without sacrificing quality or margin.

6. Key Benefits of Implementing Industrial Robots

If you’re still on the fence about introducing industrial robots to your processes, consider these major benefits:

- Improved Quality Control: Robots follow precise instructions every single time, drastically cutting down on errors.

- Enhanced Productivity: Robots can operate 24/7 with minimal downtime, boosting output and meeting tight deadlines.

- Safety & Risk Mitigation: Deploying robots in hazardous environments reduces worker exposure to accidents, chemicals, or extreme temperatures.

- Flexibility & Scalability: Modern robots with modular designs and advanced software can be redeployed to different tasks, making it easier to scale production up or down.

- Long-Term Cost Savings: While the upfront cost is considerable, the decrease in labor, rework, and wastage offers a strong return on investment (ROI).

Real-World Example of ROI

A mid-sized electronics assembly plant that integrates a fleet of SCARA robots for pick-and-place tasks might see a reduction in manual errors by up to 90%. Over five years, these savings—combined with increased throughput—often repay the initial investment multiple times.

7. Challenges and Considerations Before Adopting Robotics

Despite its numerous advantages, the path to full automation isn’t always straightforward. Here are some hurdles and considerations:

- High Initial Investment: Upfront costs can be significant—robotic arms, controllers, safety systems, and integration fees add up.

- Complex Integration: Incorporating robots into an existing production line may require rethinking factory layouts, material flow, and staff training.

- Skilled Workforce Shortage: Operating and maintaining robotic systems demands specialized knowledge, from programming to troubleshooting.

- Maintenance & Downtime: Robots may require regular software updates, calibration, and mechanical upkeep. Unplanned downtime can be costly.

- Adaptability: Not all tasks are suitable for automation. Complex, highly variable tasks may still be more efficiently handled by human operators.

Overcoming the Hurdles

- Plan Thoroughly: Conduct a comprehensive audit of your production processes to identify areas best suited for automation.

- Start Small: Begin with a pilot project or low-risk application to build internal expertise and confidence.

- Invest in Training: Upskill your existing workforce. A well-trained operator can keep a robot running at peak efficiency and troubleshoot minor issues.

- Ongoing Support: Partner with reliable vendors who offer strong after-sales support and maintenance contracts.

8. Ensuring Safety in Industrial Robotics

Safety remains paramount wherever heavy machinery is involved. Fortunately, industrial robotics has seen significant advancements to keep both workers and robots safe.

- Protective Barriers & Fencing: Traditional setups often enclose robots within safety cages to prevent inadvertent human-robot interaction during operation.

- Light Curtains & Sensors: Modern systems employ laser scanners or light curtains to detect if a person enters the robot’s workspace, immediately pausing operations if triggered.

- Emergency Stop Mechanisms: Easy-to-access E-stop buttons or pull cords ensure the system can be shut down quickly in emergencies.

- Collaborative Robot Safety: Cobots are designed with force-limiting features and sophisticated sensors to work safely alongside humans without traditional fencing.

Safety Standards & Regulations

Organizations like the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) set guidelines for robotic safety. Compliance is not just about avoiding fines—it’s about ensuring a safe working environment that fosters trust and operational stability.

9. Industries & Applications: Where Do Industrial Robots Shine?

Although automotive assembly lines were the earliest adopters, industrial robotics now spans a broad range of industries and applications:

- Automotive: From spot welding and painting to final inspections, robots are pivotal in car manufacturing.

- Electronics & Semiconductor: Miniaturized components demand high precision and repeatability, making SCARA and delta robots indispensable.

- Pharmaceutical & Medical: Sterile environments benefit from robot consistency. Tasks such as packaging, dispensing, and even surgery are increasingly robotic.

- Food & Beverage: High-speed pick-and-place tasks for sorting, packaging, and palletizing.

- Metal Fabrication & Welding: Robots excel at processes like arc welding, plasma cutting, and laser applications.

- Logistics & Warehousing: Automated Guided Vehicles (AGVs) and robotic arms handle material transportation, sorting, and packaging for swift order fulfillment.

Essentially, any sector requiring repetitive, precise, or high-speed tasks can benefit from robotics.

10. Emerging Trends and Innovations

Industrial robotics is an ever-evolving field. Some of the most exciting advancements include:

- Artificial Intelligence & Machine Learning: Intelligent robots can adapt in real time. They can identify variations in product specifications or environment changes and adjust accordingly.

- Cloud Robotics: Robots connected via the cloud can share data, learn collectively, and update software remotely, streamlining maintenance and boosting efficiency.

- Vision-Guided Robotics: Advanced cameras and sensors enable robots to perform complex tasks like bin picking, quality inspection, or even advanced assembly that relies on precise alignment.

- Robotic Simulation & Digital Twins: Virtual environments let manufacturers test new setups before physical deployment. This reduces downtime, risk, and integration costs.

- Nanorobotics & Micro Robotics: While still in early stages, micro-robots are beginning to see applications in delicate operations, including medical procedures and electronics assembly.

Technological convergence—where AI, sensors, edge computing, and networking collide—drives exponential growth in industrial robotics capabilities. That makes it an incredibly dynamic space to watch.

11. Real-World Case Studies

Concrete examples highlight the transformative power of industrial robotics.

11.1 Automotive Assembly Revamp

A global automotive manufacturer decided to replace several manual welding stations with articulated robots. The result? A 25% increase in productivity and a drastic dip in weld defects. Operators were retrained to manage the robots and perform quality checks, further enhancing the assembly line’s overall efficiency.

11.2 High-Speed Packaging Line

A food-processing company integrated delta robots for sorting and packaging baked goods. Operating alongside human workers, these robots accurately placed cookies into trays at a rate of 120 picks per minute—something previously unthinkable with manual labor. The production line throughput soared, meeting seasonal demand spikes without excessive overtime or temporary hires.

11.3 Flexible Electronics Assembly

A small-to-mid-sized electronics manufacturer sought to compete with larger rivals by adopting SCARA robots. Each robot was programmed to place tiny components on circuit boards under tight spatial constraints. Error rates dropped by 90%, and the company secured additional contracts thanks to their newfound reputation for quality.

These examples showcase how industrial robots can reshape an organization’s productivity, cost structure, and market competitiveness.

12. Common Misconceptions About Industrial Robotics

Despite the proven benefits, myths still linger around industrial robotics. Let’s debunk a few:

- “Robots Will Replace Humans Completely.”

While robots handle repetitive or hazardous tasks, humans remain indispensable for creativity, strategic thinking, and complex decision-making. - “Only Large Companies Can Afford Robots.”

Advances in technology have brought down costs. Even small and medium-sized enterprises can now access scalable robotic solutions. - “Robots Are Inflexible.”

Modern robots can be reprogrammed, retrofitted with different end effectors, and integrated with AI-driven software. They are far more adaptable than many assume. - “Maintenance Is Too Complex.”

Although specialized knowledge is beneficial, comprehensive training and vendor support make routine maintenance manageable for most facilities. - “Quality Control Is Automatic.”

Robots still require oversight. Regular calibration, software updates, and monitoring ensure consistent, high-quality output.

13. Frequently Asked Questions (FAQs)

Q1: How much does it cost to implement an industrial robot system?

Costs vary widely, ranging from $50,000 to over $500,000 depending on the robot type, payload capacity, end effector complexity, and software requirements. However, many companies realize a strong ROI within a few years due to productivity gains and reduced labor expenses.

Q2: Are collaborative robots (cobots) safe to deploy without fences or protective barriers?

Cobots come equipped with advanced safety features, including sensors that halt operation upon collision or unexpected contact. While generally safe, each deployment should undergo a thorough risk assessment, and local safety regulations must be followed.

Q3: What kind of training do operators need?

Most robotics suppliers offer in-depth training for programming, operational control, and troubleshooting. Depending on complexity, operators may need only a few days to several weeks of training.

Q4: Can one robot handle multiple tasks in different workstations?

Absolutely. Industrial robots, especially those with modular end effectors, can handle multiple tasks. With advanced path planning and quick tool-change mechanisms, you can shift the same robot between operations efficiently.

Q5: Will adopting industrial robotics disrupt my existing workforce?

A well-planned strategy focuses on upskilling employees and shifting them toward more value-added activities. While some roles may change, many companies find that robotics opens new opportunities for their workforce, rather than replacing it entirely.

14. The Future Outlook of Industrial Robotics

As technology continues to advance at breakneck speed, industrial robotics stands on the cusp of transformative changes:

- AI-Driven Autonomy: We can expect future robots to not only follow programmed instructions but also use AI models to make decisions in real time, adjusting to unpredictable scenarios.

- Global Accessibility: Lower production costs and simplified programming interfaces will put robotics technology within reach of an even broader spectrum of businesses and industries.

- Integration with Augmented Reality (AR): Technicians could use AR headsets for intuitive robot programming and real-time diagnostics, accelerating setup times and minimizing errors.

- Sustainability Focus: Next-generation robots may incorporate features aimed at energy efficiency, such as regenerative braking systems, to align with eco-conscious manufacturing.

- Human-Robot Collaboration: The advent of safer, smarter robots will make it increasingly feasible for humans and machines to share workspaces, fostering a synergy that boosts overall productivity.

In the coming years, a factory might look less like rows of machines separated from humans and more like integrated, flexible teams of people and collaborative robots. That reality stands to revolutionize not only how products are made, but also how we think about the very nature of work.

Conclusion

By now, it’s clear that industrial robotics is about more than just installing a robotic arm on the shop floor. It’s a strategic evolution—one that boosts quality, accelerates production, and transforms the workforce into higher-skilled, more empowered individuals. Whether you’re a small business considering your first robotic system or a multinational corporation seeking to optimize your existing automation, there’s no denying the massive potential for competitive advantage.

Here’s your next step:

- Start by identifying one process in your workflow that’s repetitive, prone to errors, or hazardous.

- Research how an industrial robot (or a collaborative robot) could streamline that process.

- Develop a pilot project plan, including projected costs, staff training needs, and expected ROI.

With thoughtful planning, robust training, and the right technology partner, industrial robotics can be a game-changer for your manufacturing processes. Why wait? Let us know your thoughts about industrial robotics in the comments below—are you excited by the possibilities, or do you have any lingering concerns? We’d love to hear from you!

If you want to explore more cutting-edge insights, be sure to check out our other guides at RoboticsEngineering.in. Here, you’ll find deep dives into robotic process automation, cobot case studies, and the latest trends shaping tomorrow’s factories. Your journey into industrial automation innovation starts now!