In today’s hyper-competitive manufacturing landscape, the margin for error has virtually disappeared. A single defective product can damage brand reputation, trigger costly recalls, and erode customer trust that took years to build. This is precisely why vision inspection systems have become the cornerstone of modern quality assurance strategies, particularly when integrated with robotics and automation technologies. These sophisticated systems act as tireless digital eyes, meticulously scanning for defects invisible to human inspectors while maintaining production speeds that were once thought impossible.

Recent data from the Association for Advancing Automation reveals that vision inspection systems in manufacturing have reduced quality control costs by up to 63% while improving defect detection rates by over 97% compared to traditional manual inspection methods. With the global machine vision market projected to reach $18.24 billion by 2025, manufacturers who fail to adopt these technologies risk falling critically behind their competitors.

This comprehensive guide explores how vision inspection systems work in conjunction with robotics and automation to revolutionize manufacturing quality control, boost efficiency, and deliver unprecedented product consistency.

Table of Contents

What Are Vision Inspection Systems in Manufacturing?

Definition and Core Components

Vision inspection systems represent the sophisticated integration of advanced imaging technology with computational analysis to automatically inspect, evaluate, and verify product quality and performance. Unlike human inspectors who experience fatigue, inconsistency, and limitations in speed, these systems operate with unwavering precision around the clock.

A complete vision inspection system in manufacturing typically consists of these essential components:

- Cameras and Image Sensors: High-resolution industrial cameras (area scan or line scan) that capture detailed images of products on the production line

- Illumination Systems: Specialized lighting configurations (backlighting, ring lights, dome lights) that enhance visibility of critical features

- Optics and Lenses: Precision lenses that focus on specific inspection areas and accommodate various working distances

- Image Processing Hardware: Industrial-grade computers or embedded systems that analyze captured images

- Software and Algorithms: Advanced algorithms that detect anomalies, measure dimensions, verify assembly, and identify defects

- Communication Interfaces: Protocols that integrate with broader automation systems, PLCs, and robotic controllers

- Mechanical Fixtures: Precision mounting systems that ensure consistent positioning for reliable imaging

Types of Vision Inspection Technologies

The field of vision inspection encompasses several specialized technologies, each suited to different manufacturing requirements:

2D Vision Systems: The most common implementation, these systems capture standard two-dimensional images to inspect surface features, verify part presence, check labels, and measure dimensions. They excel in applications where defects can be detected from a single viewing angle.

3D Vision Systems: Using techniques like laser triangulation, structured light, or stereoscopic imaging, these systems generate three-dimensional representations of products. This approach is invaluable for inspecting complex geometries, measuring depth, and detecting subtle variations in product topography.

Hyperspectral Imaging: Moving beyond the visible spectrum, hyperspectral systems capture data across multiple wavelengths, including infrared and ultraviolet. This technology can detect material composition differences, chemical variations, and defects invisible to standard cameras.

Thermal Imaging: By measuring heat signatures, thermal vision systems can identify internal defects, detect overheating components, or verify proper curing or cooling processes that wouldn’t be visible through conventional imaging.

X-Ray and CT Scanning: For the most demanding inspection requirements, these technologies see completely through products to inspect internal components, solder joints, or structural integrity without disassembly.

The Integration of Vision Systems with Robotics and Automation

Vision-Guided Robotics: The Perfect Manufacturing Partnership

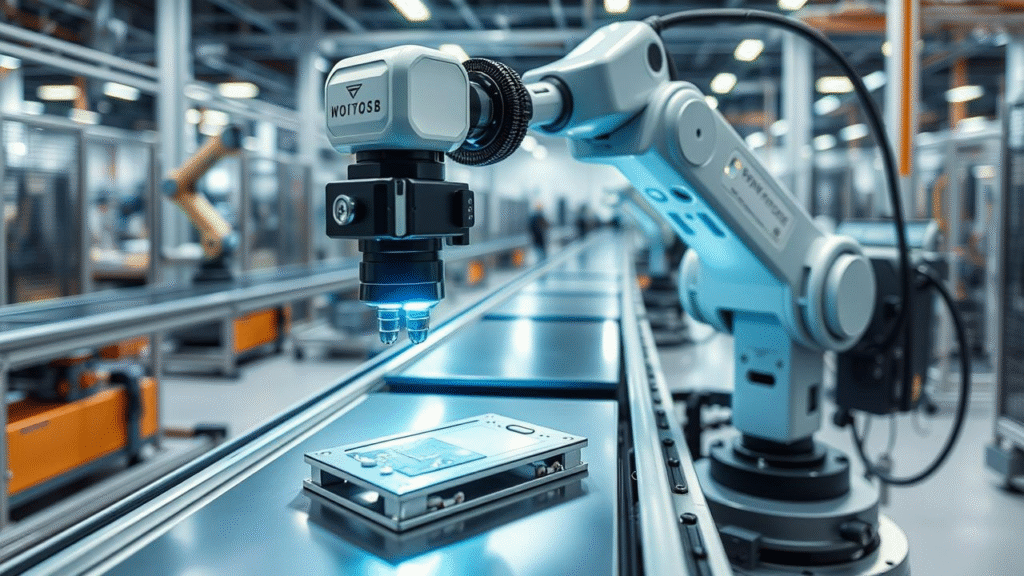

The true revolutionary potential of vision inspection emerges when these systems are integrated with robotics and broader automation technologies. Vision-guided robotics (VGR) combines the sensory capabilities of machine vision with the physical manipulation abilities of robots to create flexible, adaptive manufacturing cells.

Key Integration Architectures

Robot-Mounted Cameras: When cameras are directly attached to robotic arms, the system gains tremendous flexibility. The robot can move the camera to multiple inspection angles, adjust for different product variants, and even perform active inspections during assembly processes.

Stationary Multi-Camera Arrays: For high-speed production lines, fixed camera arrays observe products as they pass by, with robotic systems responding to inspection results by removing defective items or adjusting subsequent manufacturing steps.

Collaborative Robot Integration: Cobots equipped with vision capabilities work alongside human operators, handling repetitive inspection tasks while humans manage more complex quality decisions and oversight functions.

Real-Time Feedback Loops in Automated Systems

Modern vision inspection systems don’t simply identify defects—they actively participate in process improvement through sophisticated feedback mechanisms:

Adaptive Manufacturing: When vision systems detect a trend of minor deviations, they can communicate with upstream equipment to make real-time adjustments, preventing potential defects before they occur.

Statistical Process Control Integration: By continuously monitoring critical quality parameters, vision systems collect valuable data that feeds into SPC systems, enabling predictive maintenance and ongoing process optimization.

Closed-Loop Quality Systems: The complete integration of inspection, analysis, and correction creates a self-improving manufacturing environment where quality improves automatically over time.

Key Applications of Vision Inspection Systems in Modern Manufacturing

Precision Electronics Manufacturing

In electronics manufacturing, where component sizes continue to shrink and assembly density increases, vision inspection systems have become indispensable:

PCB Inspection: Automated optical inspection (AOI) systems verify correct component placement, solder joint quality, and circuit integrity at speeds impossible for human inspectors.

Semiconductor Fabrication: Wafer inspection systems detect microscopic defects in silicon wafers and finished chips, ensuring reliability in critical applications.

Display Manufacturing: Vision systems verify pixel integrity, color uniformity, and structural quality in LCD, OLED, and other display technologies.

Automotive Industry Applications

Vehicle manufacturing combines high volumes with critical safety requirements, making it an ideal application for vision inspection:

Body Panel Inspection: Vision systems verify panel alignment, gap consistency, paint quality, and surface finish to ensure perfect aesthetic appearance.

Safety Component Verification: Critical parts like airbag modules, brake components, and steering systems undergo 100% inspection to prevent potential failures.

Assembly Verification: Robots with integrated vision confirm proper installation of components, presence of fasteners, and correct routing of wires and hoses.

Pharmaceutical and Medical Device Manufacturing

Few industries have higher quality standards than pharmaceutical and medical device manufacturing:

Tablet and Capsule Inspection: Vision systems verify medication color, size, shape, and integrity while identifying foreign particles or defects.

Packaging Verification: Systems ensure proper labeling, expiration dates, lot codes, and package integrity to prevent costly recalls and regulatory issues.

Medical Device Assembly: Vision-guided robots assemble intricate medical devices with microscopic precision while verifying correct component placement.

Food and Beverage Production

Consumer safety and product consistency drive vision inspection adoption in food processing:

Foreign Object Detection: Vision systems identify non-food contaminants that might be missed by metal detectors or X-ray systems.

Label and Date Code Verification: Systems ensure products display accurate ingredient lists, nutrition facts, and expiration information.

Fill Level and Seal Integrity: Vision inspection verifies proper filling and sealing of containers to maintain product freshness and prevent leakage.

Advanced Features of Modern Vision Inspection Systems

Artificial Intelligence and Deep Learning Applications

The integration of AI and machine learning has dramatically expanded the capabilities of vision inspection systems:

Defect Classification: AI algorithms not only detect anomalies but classify them by type, severity, and probable cause, enabling targeted process improvements.

Self-Learning Systems: Modern vision systems improve their detection capabilities over time, learning from new examples and reducing false positives.

Adaptive Inspection Parameters: AI-powered systems can automatically adjust inspection criteria based on changing product variations, lighting conditions, or material characteristics.

Multi-Spectral and Hyperspectral Analysis

Moving beyond visible light inspection has opened new quality control possibilities:

Material Authentication: Hyperspectral imaging can verify the composition of raw materials before they enter production processes.

Contamination Detection: Systems can identify bacterial contamination, chemical residues, or organic degradation invisible to standard cameras.

Internal Structure Analysis: Near-infrared and other spectral ranges can evaluate internal characteristics without destructive testing.

3D Reconstruction and Volumetric Analysis

Three-dimensional inspection capabilities continue to advance with new techniques:

Complete Geometric Verification: Products can be digitally reconstructed and compared to CAD models for comprehensive dimensional verification.

Volume Measurement: Systems can precisely calculate volumes of irregular shapes for proper filling operations or material usage optimization.

Surface Topography Analysis: Microscopic surface variations can be mapped and analyzed to verify proper finishing, coating application, or texture characteristics.

Implementation Challenges and Solutions

Common Integration Obstacles

Despite their benefits, vision inspection systems present implementation challenges:

Lighting Variability: Inconsistent illumination can cause false readings and missed defects.

Solution: Engineered lighting environments with controlled spectrum, direction, and intensity plus software compensation for variations.

Speed vs. Resolution Tradeoffs: Increasing production speeds can reduce image quality and detection accuracy.

Solution: Specialized high-speed cameras, parallel processing architectures, and optimized algorithms designed for specific inspection tasks.

Product Variation Handling: Natural variation in products can trigger false rejections.

Solution: Machine learning algorithms that understand acceptable variation ranges and adapt to different product variants.

Practical Implementation Steps

For manufacturers considering vision inspection implementation, a structured approach delivers the best results:

- Define Inspection Requirements: Clearly document what features need inspection, acceptable tolerance ranges, and required throughput rates.

- Select Appropriate Technology: Choose cameras, lenses, lighting, and processing hardware matched to your specific inspection challenges.

- Develop Custom Algorithms: Work with vision system integrators to create detection algorithms optimized for your products and defect profiles.

- Integration and Testing: Implement the system in a controlled environment before full production deployment, refining parameters and resolving issues.

- Operator Training: Ensure staff understands system operation, maintenance requirements, and how to interpret results.

- Ongoing Calibration and Validation: Establish regular validation procedures to maintain system accuracy and reliability.

ROI and Business Impact of Vision Inspection Systems

Quantifiable Benefits

Vision inspection systems deliver measurable returns across multiple business metrics:

Quality Improvements: Manufacturers typically report 90-99% reduction in defect escape rates after implementing vision inspection.

Labor Cost Reduction: Automated inspection reduces quality control staffing requirements by 30-70% while improving consistency.

Reduced Warranty Claims: By preventing defective products from reaching customers, warranty costs often decrease by 40-60%.

Improved Production Speed: Many manufacturers achieve 15-25% throughput increases when manual inspection bottlenecks are eliminated.

Regulatory Compliance: Automated inspection with complete documentation helps meet stringent industry requirements and simplifies audits.

Calculating Return on Investment

When evaluating vision inspection systems, consider these ROI factors:

Initial Investment: Hardware, software, integration services, and training costs

Ongoing Expenses: Maintenance, calibration, updates, and possible sensor replacement

Direct Savings: Reduced labor costs, fewer returns, decreased scrap, and lower rework expenses

Indirect Benefits: Improved brand reputation, increased customer satisfaction, and potential premium pricing opportunities

Most manufacturers see complete ROI within 12-24 months, with some high-volume operations recouping costs in as little as 6 months.

Future Trends in Vision Inspection Technology

Emerging Technologies on the Horizon

The vision inspection landscape continues to evolve with these emerging innovations:

Edge Computing Architecture: Processing images directly at the camera level reduces latency and enables faster decision-making in high-speed environments.

Quantum Dot Sensors: Next-generation image sensors promise higher sensitivity, better low-light performance, and expanded spectral ranges.

Digital Twin Integration: Vision systems will increasingly feed data into digital twin models, creating virtual representations of production lines for simulation and optimization.

Neuromorphic Vision Systems: Inspired by human visual processing, these systems mimic the brain’s neural networks for more efficient and adaptive inspection.

The Path Toward Autonomous Manufacturing

The ultimate evolution of vision inspection systems points toward completely autonomous manufacturing:

Self-Optimizing Production: Vision systems will continuously adjust manufacturing parameters to maximize quality without human intervention.

Predictive Quality Analytics: Advanced systems will identify quality trends and predict potential issues before they manifest as defects.

Complete Vertical Integration: From incoming materials to finished products, interconnected vision systems will ensure end-to-end quality control across the entire manufacturing ecosystem.

Case Studies: Vision Inspection Success Stories

Automotive Electronics Manufacturer

A tier-one automotive supplier implemented a robotic vision inspection system for PCB assembly verification with remarkable results:

- Defect detection rate improved from 92% to 99.7%

- Production speed increased by 35% due to elimination of manual inspection

- Warranty claims decreased by 62% in the first year

- Complete ROI achieved within 9 months of implementation

Pharmaceutical Packaging Operation

A major pharmaceutical company deployed a multi-camera vision system for label and package verification:

- Zero recall incidents in the three years following implementation

- Regulatory compliance documentation automated and simplified

- Labor costs reduced by 42% while increasing throughput by 28%

- System paid for itself primarily through elimination of potential recall costs

Food Processing Implementation

A ready-meal manufacturer integrated vision inspection for foreign object detection and packaging verification:

- Customer complaints regarding foreign objects dropped to zero

- Production line efficiency improved by 22% through reduction in false rejections

- Insurance premiums decreased due to improved risk profile

- Brand reputation strengthened as a quality leader in the category

Conclusion: The Imperative of Vision Inspection Adoption

As manufacturing continues its evolution toward Industry 4.0, vision inspection systems have transcended their original role as simple quality control tools to become central nervous systems for intelligent production environments. By bridging the gap between physical production and digital analysis, these systems deliver the precision, consistency, and data integration essential for competitive manufacturing.

The integration of vision inspection with robotics and automation represents not merely an incremental improvement but a fundamental transformation in how quality is managed, measured, and maintained. Manufacturers who embrace these technologies position themselves for higher productivity, better quality outcomes, and greater agility in responding to changing market demands.

As costs continue to decrease and capabilities expand, the question for manufacturers is no longer whether to implement vision inspection systems, but how quickly they can be deployed to remain competitive in an increasingly quality-conscious marketplace.

References and Further Reading

- International Society for Optics and Photonics (SPIE). (2023). Machine Vision Handbook: Industrial Applications and Implementation.

- Journal of Manufacturing Systems. (2023). “Deep Learning Applications in Automated Visual Inspection: A Comprehensive Review.”

- Vision Systems Design Magazine. (2024). “Hyperspectral Imaging in Food Safety Applications.”

- International Journal of Production Research. (2023). “Economic Analysis of Machine Vision Implementation in Automotive Manufacturing.”

- American Society for Quality. (2024). Quality 4.0: The Role of Vision Systems in Smart Manufacturing.

- National Institute of Standards and Technology. (2023). Machine Vision Measurement Accuracy Standards.

- IEEE Transactions on Automation Science and Engineering. (2024). “Collaborative Robot-Vision Systems for Flexible Manufacturing.”