Manufacturing Robots: Your In-Depth Guide to Transforming Modern Production

Table of Contents

1. Introduction: Why Manufacturing Robots Matter

Have you ever wondered how some factories can churn out thousands of perfect products every hour without missing a beat? The answer often lies in manufacturing robots—the advanced robotic systems that take efficiency, consistency, and innovation in production to an entirely new level. If you’re running a manufacturing line or simply curious about where the future of industrial automation is headed, you’re in the right place. In this comprehensive guide, we’ll explore every facet of modern manufacturing robots, from their historical roots to their cutting-edge applications in high-speed assembly lines.

By the end of this article, you’ll understand why manufacturing robots are essential in today’s Industry 4.0 environment, how they can solve real-world production challenges, and what it takes to integrate them seamlessly into your operations. Ready to find out more? Let’s get started.

2. A Quick History of Manufacturing Robots

The journey of manufacturing robots begins in the mid-20th century with the first automated machines designed to handle repetitive tasks. However, the concept truly took off in the 1960s when General Motors adopted the Unimate, a rudimentary robotic arm that could move heavy parts on an assembly line. This groundbreaking adoption hinted at the extraordinary potential of industrial robotics—precision, reliability, and tirelessness.

Over the decades, robots have evolved dramatically:

- 1970s: Introduction of more sophisticated servo motors and controllers.

- 1980s: Widespread adoption in the automotive sector. Sensor technology improved, offering rudimentary machine vision.

- 1990s: Refinement of control software and hardware integration, enabling better speed and accuracy.

- 2000s: Emergence of collaborative robots (cobots) that operate safely alongside humans.

- Today: AI-driven, sensor-rich systems that learn and adapt in real time, drastically improving quality and throughput.

The evolution continues, and we’re now witnessing a wave of hyper-connected, machine-learning-based systems that promise greater agility and autonomy in manufacturing.

3. How Manufacturing Robots Are Revolutionizing Industry 4.0

The rise of Industry 4.0—often characterized by the fusion of digital technologies, data analytics, and automation—has pushed manufacturing robots into the spotlight. At the heart of Industry 4.0 is the concept of a “smart factory,” where machinery, sensors, and software operate as a unified ecosystem. Within this ecosystem, manufacturing robots shine:

- Adaptive Learning: Advanced robots can use machine learning to optimize their tasks, reduce errors, and even predict maintenance issues before they occur.

- Interconnected Systems: Thanks to the Industrial Internet of Things (IIoT), robots constantly exchange data with other devices, creating a seamless flow of information.

- Scalable Operations: Whether you’re a small startup or a multinational corporation, modern robotic solutions can scale to your production needs.

It’s this marriage of robotics, data, and connectivity that defines the future of manufacturing.

4. Types of Manufacturing Robots

Understanding the major categories of manufacturing robots is crucial for selecting the right system for your operation. Below are the most common types you’ll encounter.

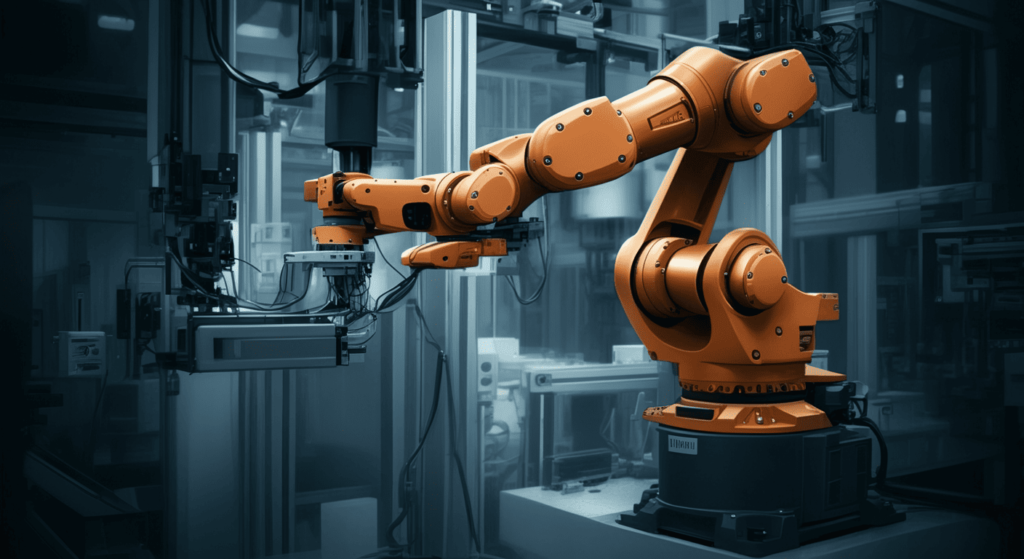

1. Articulated Robots

Articulated robots have rotary joints (usually between four and six axes), resembling a human arm. Their jointed structure offers the highest degree of flexibility in motion, making them ideal for:

- Welding

- Painting

- Assembly

- Pick-and-place tasks

They’re popular in industries where a wide range of movement is essential, such as automotive production lines.

2. SCARA Robots

SCARA (Selective Compliance Articulated Robot Arm) robots offer horizontal flexibility while maintaining rigidity in the vertical axis. Typically found in small-parts assembly, packaging, or electronic board manufacturing, SCARAs excel in fast, precise movements.

3. Cartesian Robots

Cartesian robots (also known as gantry or linear robots) move in straight lines along the X, Y, and Z axes. They’re simpler in design but highly accurate. You’ll find these in tasks that require:

- Straight-line precision

- Stacking

- 3D printing

- CNC machine loading

Their straightforward design often makes them more cost-effective and easier to program.

4. Collaborative Robots (Cobots)

Cobots are built to work alongside human operators in shared workspaces. Thanks to advanced sensor arrays, force-limiting features, and safety protocols, they can operate without extensive safety barriers. Typical uses include:

- Light assembly

- Finishing tasks requiring human finesse

- Material handling

Cobots cater especially well to small and medium-sized enterprises (SMEs) looking to automate without reorganizing entire facilities.

5. Delta Robots

Delta robots use parallel linkages arranged in a triangular or delta formation. Due to their lightweight arms and agile configuration, delta robots specialize in:

- High-speed pick-and-place

- Sorting applications

- Lightweight product assembly

You’ll see them in food packaging lines, pharmaceutical products, or electronics where speed is paramount.

5. Real-World Applications

While the theoretical possibilities of manufacturing robots are nearly endless, their real-world uses are even more compelling. Below are some of the sectors where these robots truly shine.

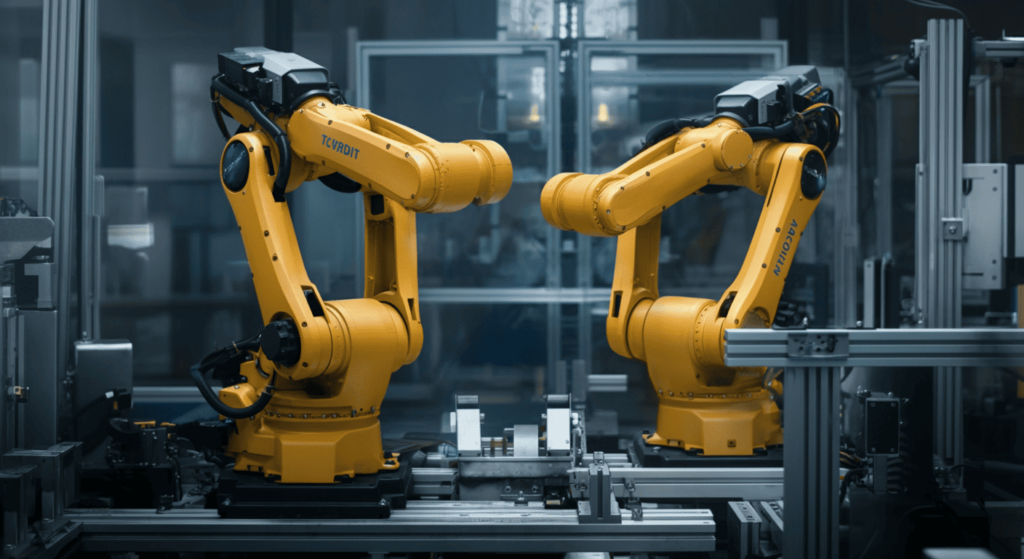

Automotive Assembly

When you think of industrial robots, automotive assembly lines likely come to mind first. Robotic arms handle tasks from welding car frames to painting exteriors. Their ability to operate consistently at high speed has revolutionized the automotive industry, allowing for:

- Reduced errors and variability

- Accelerated production schedules

- Enhanced worker safety, as robots take on hazardous tasks

Electronics Manufacturing

Electronics manufacturers rely on robots for precision in soldering and component placement, particularly for smartphones, circuit boards, and other delicate equipment. Here, the margin for error is virtually zero, and robots excel at repetitive tasks that require microscopic accuracy.

Food and Beverage Processing

Food safety regulations demand stringent handling processes to avoid contamination. Robots assist with tasks such as:

- Sorting

- Packaging

- Quality control checks

With built-in vision systems, some can even detect defects or contamination in products, improving both efficiency and safety.

Pharmaceutical and Medical Devices

Cleanroom environments in pharmaceutical and medical device manufacturing benefit enormously from robotic systems. Robots can:

- Assemble complex medical devices

- Fill vials

- Sort and organize delicate components

Their consistency ensures that drugs and devices meet stringent regulatory requirements.

Metals and Heavy Machinery

In facilities dealing with steel, aluminum, or heavy machinery parts, robots take over risky tasks such as forging, cutting, and welding large metal components. This automation boosts safety and operational throughput while reducing liability and resource wastage.

6. Key Components and Technologies That Power Manufacturing Robots

The complexity of manufacturing robots doesn’t just come from their mechanical arms or joints. A range of sophisticated components and technologies work together to deliver exceptional performance and adaptability.

Sensors and Vision Systems

Modern robots are packed with sensors—proximity sensors, torque sensors, temperature sensors, and more. Vision systems use cameras and image-processing algorithms to:

- Identify parts

- Determine orientation

- Measure quality

These capabilities allow robots to make real-time adjustments, drastically cutting down on mistakes and scrap.

Machine Learning and AI Integration

Machine learning algorithms enable robots to learn from experience. By analyzing data from sensors, AI-driven systems can predict component wear, optimize motion patterns, and even propose design changes for efficiency. This continuous learning environment makes today’s manufacturing robots both adaptive and proactive.

End-Effector Design

The “hand” of the robot, or end-effector, is crucial for tasks such as gripping, welding, cutting, or painting. End-effectors can be:

- Grippers (vacuum or mechanical)

- Welding torches

- Soldering irons

- Specialized attachments like sprayers

Selecting the right end-effector can make or break your automation project.

Connectivity and IIoT

Manufacturing robots often act as vital nodes in an IIoT ecosystem. By communicating performance data to cloud platforms and other machines, robots help orchestrate a seamless and data-driven production process. This connectivity also allows for remote monitoring and rapid troubleshooting, further minimizing downtime.

7. Designing a Smart Factory for Robotic Integration

If your goal is to adopt a fleet of manufacturing robots, you’ll need a smart factory environment to match. Here are critical steps in designing such a facility:

- Conduct a Readiness Assessment: Evaluate your current processes, technologies, and skill sets to see how prepared you are for a robotic overhaul.

- Map Data Flow: Ensure all machines and robots can share critical data in real time.

- Modular Layout: Create flexible production cells that can be reconfigured as needs change.

- Scalable IT Infrastructure: Robust networks, cloud services, and cybersecurity measures are non-negotiable.

- Workforce Training: Train employees to work collaboratively with robots. Upskilling your team ensures smooth operation and fosters innovation.

A well-planned smart factory isn’t just about installing robots; it’s about creating a cohesive ecosystem where each component—human and machine—operates in synergy.

8. Benefits of Using Manufacturing Robots

Why invest significant capital and time into robotic automation? The benefits speak for themselves.

1. Increased Productivity

Robots don’t tire, take breaks, or require shift changes. They work around the clock, boosting overall throughput. In many cases, production lines that incorporate robots witness a marked increase in units produced per hour, helping companies meet tight deadlines or scale operations.

2. Enhanced Precision and Quality

In manufacturing—especially in electronics or medical devices—minute inconsistencies can lead to product failures or recalls. Manufacturing robots excel at delivering high-precision, repeatable movements. This reliability significantly reduces errors, ensuring consistent product quality.

3. Cost Efficiency and ROI

While the upfront investment in robotic systems can be significant, the long-term return on investment (ROI) often justifies the cost. Robots reduce material wastage, lower defect rates, and optimize labor expenses over time. Thanks to advancements in technology, the cost barrier to entry is also decreasing, opening the door for smaller manufacturers.

4. Improved Workplace Safety

Automation allows robots to perform tasks that pose high risks to human workers, such as handling hazardous materials or operating in extreme temperatures. This shift not only safeguards employees but also reduces potential costs related to workplace accidents.

5. Scalability and Flexibility

Modern robots—especially cobots—are designed for plug-and-play adaptability. Need to switch from producing one product to another? Reprogram the robot, swap out the end-effector if necessary, and you’re up and running in no time.

9. Step-by-Step Guide to Implementing Robotic Automation

Thinking of adopting manufacturing robots in your facility? Here’s a straightforward roadmap:

- Identify the Use Case

- Pinpoint tasks that are repetitive, hazardous, or require extreme precision.

- Conduct a Feasibility Study

- Evaluate potential ROI, cost savings, and operational impact.

- Choose the Right Robot Type

- Articulated, SCARA, Delta, or Cobots? The choice depends on your production needs.

- Engage Stakeholders

- Include operators, engineers, managers, and even clients in planning to ensure smooth adoption.

- Plan the Layout

- Consider space requirements, safety zones, and integration with existing equipment.

- Integration and Testing

- Work with robotics experts or system integrators to ensure seamless installation. Conduct pilot runs and quality checks.

- Training and Documentation

- Offer comprehensive training to operators, managers, and maintenance teams. Keep detailed records for maintenance and updates.

- Scale Up

- After successful implementation in one area, roll out automation across other processes as needed.

Approaching robotic automation methodically ensures minimal disruptions and maximizes the value you gain.

10. Common Misconceptions About Manufacturing Robots

No transformative technology is free from myths. Here are some widespread misconceptions:

- “Robots Will Replace All Human Jobs.”

In reality, robots handle repetitive or dangerous tasks, freeing humans to focus on complex or creative aspects of work. Historically, automation has led to job shifts rather than outright eradication. - “They’re Too Expensive for Small Businesses.”

While top-of-the-line systems can be costly, the market now offers scalable solutions for SMEs. Leasing and pay-per-use models also lower entry barriers. - “Robots Are Inflexible.”

Modern systems, especially cobots, are highly adaptable. With reprogramming, a robot can shift between tasks in a matter of hours, if not minutes. - “Maintenance Is Prohibitively Complex.”

Maintenance does require specialized skills, but most manufacturers provide training and support services. Predictive maintenance tools also simplify the process, reducing the likelihood of sudden breakdowns. - “Only Tech Giants Benefit from Automation.”

From a small bakery using pick-and-place robots for packaging pastries to a midsize electronics firm automating PCB assembly, businesses of all scales reap rewards.

11. FAQs

Q1: How do I choose the right manufacturing robot for my industry?

A: Start by mapping out your specific requirements—payload, speed, precision, and workspace constraints. Consult with a robotics integrator for a detailed analysis of your workflow and to match you with a suitable robot type (articulated, SCARA, etc.).

Q2: What is the typical ROI period for manufacturing robots?

A: Return on investment can range from 12 to 36 months, depending on factors like labor costs, production volume, and the complexity of integration. High-volume operations generally recoup costs faster due to economies of scale.

Q3: Can robots handle sensitive tasks requiring a human’s ‘touch’?

A: Collaborative robots (cobots) equipped with force sensors and advanced AI can perform tasks that require delicate handling. While they can’t replicate every nuance of human touch, they’re rapidly improving in dexterity.

Q4: Do I need a separate team to manage and program these robots?

A: Not always. Modern cobots and some industrial robots feature intuitive programming interfaces that don’t require advanced coding skills. That said, having at least one technician or engineer on staff who understands robotic systems is highly beneficial.

Q5: Is it difficult to transition from manual processes to robotic automation?

A: The initial setup can be challenging, particularly if your team is new to robotics. However, thorough planning, training, and possibly working with an experienced system integrator can streamline the transition significantly.

12. Pro Tips for Maximizing Efficiency

- Leverage Real-Time Analytics:

Use software tools that track your robot’s performance metrics, such as cycle time, downtime, and error rates. This data can pinpoint inefficiencies and guide corrective actions. - Standardize Processes:

Consistency in raw materials, component shapes, and packaging sizes makes robotic tasks far more predictable and efficient. - Optimize End-Effector Design:

Whether you’re using grippers or specialized tools, ensure the end-effector is precisely tailored to your product’s shape, texture, and weight. - Regular Preventive Maintenance:

Create a schedule for inspecting motors, joints, and sensors. Simple routines like lubrication and sensor calibration can dramatically extend a robot’s lifespan. - Stay Current with Software Updates:

Software refinements often include improved motion algorithms, bug fixes, and support for new sensor technologies. Keeping your system updated can translate to measurable gains in speed and accuracy. - Invest in Team Training:

Even the most advanced robots need skilled humans for oversight, programming tweaks, and emergency interventions. A well-trained workforce is your best insurance against unexpected issues.

13. Measuring Success: KPIs and Metrics

Effective measurement of robotic automation success goes beyond raw output. Consider monitoring these KPIs:

- Cycle Time: The time it takes for a robot to complete one full operation.

- Uptime Percentage: Ensures you’re maximizing production.

- Defect Rate: A low defect rate indicates optimal performance and consistent quality.

- Downtime Causes: Tracking the reasons for downtime helps you address root issues, whether it’s mechanical failures or supply chain hiccups.

- Energy Consumption: Modern robots are more energy-efficient than their predecessors, but monitoring usage can further optimize costs.

Regular audits of these metrics guide you in fine-tuning your processes and making informed decisions about expansions or upgrades.

Conclusion

Whether you’re a seasoned industry professional or a newcomer eager to modernize your operations, manufacturing robots offer transformative potential. From boosting output and quality to minimizing workplace hazards, these robotic systems are reshaping what’s possible in industrial production. Far from relegating human roles to the sidelines, they open up new job categories and creative opportunities to enhance your business.

What’s your take on manufacturing robots? Have you already integrated them into your workflows, or are you still in the planning phase? We’d love to hear your experiences, challenges, or questions. Drop a comment below, and let’s get the conversation started.

Ready to Dive Deeper?

- Check Out Our Other Guides: If you found this helpful, explore our resources on robotic programming, sensor selection, and more on roboticsengineering.in.

- Subscribe for Updates: Sign up for our newsletter to stay updated on the latest trends, tips, and tutorials in industrial robotics.

By leveraging these insights, you’ll be better equipped to bring your production lines into the era of Industry 4.0, outrank your competition in operational efficiency, and provide unmatched value to your customers. Embrace the future today—your smart factory journey begins now.