Paddle Dryer: Efficient Industrial Drying Solutions for Bulk Materials

A paddle dryer is a specialized machine designed to dry, heat, cool, or even react with various materials efficiently. It works by using heated, rotating paddles inside a sealed cylinder, allowing for indirect heat transfer that ensures uniform drying without direct contact with the heat source. This method makes it ideal for handling sticky, wet, or sensitive substances that other drying methods might struggle with.

You’ll find paddle dryers used across industries where controlled drying is essential, such as chemicals, food, pharmaceuticals, and sludge treatment. Because of their versatility, they can also handle tasks like pasteurization and crystallization, making them more than just a typical dryer.

Understanding how a paddle dryer operates and its key advantages can help you choose or optimize the right equipment for your process. This guide will break down what makes paddle dryers efficient and why they might be the solution you need for your drying challenges.

Table of Contents

What Is a Paddle Dryer?

A paddle dryer is an industrial machine designed to remove moisture from various materials efficiently. It operates through indirect heating and mechanical agitation, ensuring uniform drying while handling sensitive or viscous substances. Understanding its design, components, and operation helps you optimize its use in your drying process.

Definition and Basic Principles

A paddle dryer is an indirect thermal drying system. It uses heated surfaces that transfer heat without direct contact with the material. This indirect method prevents overheating or burning of heat-sensitive products such as sludge, powders, or pastes.

The machine continually agitates the material with rotating paddles. This agitation improves heat distribution and prevents clumping or sticking. The combination of heat and mixing evaporates moisture steadily, producing a dry, stable final product.

Key Components

The main parts of a paddle dryer include a cylindrical drum or trough, rotating shafts, and multiple paddles fixed on the shafts. The drum has heated surfaces, often created by steam or hot oil flowing inside.

The paddles are wedge-shaped or flat, designed to stir, scrape, and move the material. Seals prevent air leakage and maintain controlled drying conditions. You will also find a discharge outlet to remove the dried product and an inlet for feeding wet material.

How Paddle Dryers Work

You load wet material into the dryer’s drum. As the paddles rotate, they continuously scrape and mix the material over the heated surface. Heat transfers indirectly from the drum wall or internal jackets to the material, evaporating moisture.

The motion ensures even exposure to heat, improves drying speed, and reduces buildup on surfaces. Vapor generated is vented out, while the dried material moves toward the outlet. You can control parameters like temperature and rotation speed to suit your specific drying needs.

Types of Paddle Dryers

Paddle dryers come in various designs tailored for specific drying needs. They differ mainly in their operation mode and the environment in which drying occurs. Understanding these types helps you select the most appropriate one for your application.

Batch Paddle Dryers

Batch paddle dryers operate in a controlled, cyclical process. You load the material, dry it, and then unload after the cycle completes. This type is ideal for small to medium volumes or when you need precise control over drying time and conditions.

The design features a horizontal cylindrical vessel with rotating paddles that agitate the material for uniform drying. Heat is transferred indirectly through the vessel walls or hollow paddles, usually by steam or thermal oil. This method reduces thermal degradation of sensitive materials.

Batch dryers offer flexibility when drying various materials because you can adjust operating parameters between batches. However, they might be less efficient for very large-scale or continuous production processes.

Continuous Paddle Dryers

Continuous paddle dryers maintain an ongoing drying operation, which suits high-volume production. You feed material continuously and collect dried output simultaneously, making it efficient for processing large batches without downtime.

The equipment includes a cylindrical vessel with multiple paddles mounted on a rotating shaft, agitating the material to maintain uniform heat distribution. The heating medium circulates through the vessel walls and agitator shaft, providing consistent indirect heat transfer.

You benefit from steady throughput and more consistent product quality under stable operating conditions. Continuous dryers typically have a compact footprint and lower labor requirements compared to batch systems.

Vacuum Paddle Dryers

Vacuum paddle dryers operate under reduced pressure, lowering the boiling point of liquids within the material. This allows drying at comparatively low temperatures, which is important when handling heat-sensitive or volatile substances.

The system consists of a sealed cylindrical vessel with rotary paddles and a vacuum chamber. The vacuum environment minimizes oxidation and thermal damage to your product, preserving quality.

These dryers are common in pharmaceuticals, chemicals, and foods where exposure to heat must be limited. Vacuum paddle dryers can efficiently remove moisture while maintaining delicate properties through gentle agitation and controlled heating.

Paddle Dryer Design and Construction

You’ll find paddle dryers designed to maximize heat transfer while ensuring efficient and controlled drying. Key considerations include the materials selected for durability and corrosion resistance, the specific arrangement of paddles for optimal contact and mixing, and the sealing and insulation methods to maintain temperature and prevent leaks.

Materials of Construction

Your paddle dryer’s materials must withstand thermal stress and chemical exposure. Commonly, stainless steel is used owing to its corrosion resistance and strength at high temperatures. For more aggressive or corrosive substances, Hastelloy offers enhanced durability.

The drying vessel, paddles, and hollow shafts are typically fabricated from these metals to ensure longevity and comply with safety standards such as the ASME Pressure Vessel Code. This also supports capacities ranging from a few liters to tens of thousands, depending on your process needs.

Choosing the right material affects maintenance frequency and operational costs. You want resistance to wear and minimal contamination while maintaining thermal conductivity for efficient drying.

Paddle Arrangement

The paddle layout directly impacts drying efficiency and product homogeneity. Typically, paddles are wedge-shaped and mounted on hollow shafts, which circulate heating media internally. You will see configurations with two to four sets of paddles rotating simultaneously.

This multi-paddle arrangement continuously renews the drying surface, improving heat transfer and agitation. The paddles’ rotation is scaled to your material’s viscosity and drying rate, allowing you to process sludges, powders, or granules evenly.

Spacing and angle are designed to minimize material buildup and avoid thermal degradation by preventing hot spots. This setup provides consistent drying without the need for high temperatures.

Sealing and Insulation

Sealing is crucial to preventing vapor and heat loss during operation. Paddle dryers incorporate specialized seals at shaft entries to maintain vacuum conditions if needed and to keep contaminants out.

Your seal design often involves mechanical seals or packed glands suited for the operating pressure and temperature. Reliable sealing supports the removal of moisture or solvents under reduced temperatures in vacuum systems.

Insulation surrounds the jacketed shell to reduce heat loss, improving energy efficiency. Depending on your installation, you may find mineral wool or ceramic fiber insulation used to ensure temperature stability and operator safety.

Applications of Paddle Dryers

Paddle dryers are used in industries where controlled drying of materials is critical. They provide precise moisture removal while preventing overheating and degradation, making them suitable for sensitive and bulk materials alike.

Chemical Industry

In the chemical sector, you utilize paddle dryers primarily for drying bulk chemicals, intermediates, and by-products. These dryers handle sticky, viscous, or heat-sensitive compounds effectively, due to their indirect heating and mechanical agitation.

You benefit from uniform heat distribution through rotating hollow paddles and a heated jacket, which minimizes hotspots. This process improves product quality by maintaining chemical stability and reduces waste by thoroughly drying residual moisture.

Common chemical applications include drying polymers, catalysts, pigments, and salts. Whether dealing with fine powders or slurry-like materials, paddle dryers provide consistent output and adaptability to varying material characteristics.

Pharmaceutical Processing

Pharmaceutical manufacturing demands precise moisture control to ensure drug safety and efficacy. Paddle dryers support this need by offering gentle drying conditions that avoid overheating sensitive active pharmaceutical ingredients (APIs) and excipients.

You can dry powders, granules, and sludge with controlled temperature and vacuum options, protecting compound integrity. The equipment’s design also helps prevent cross-contamination through easy cleaning and closed-system operation.

In addition, the ability to operate under vacuum conditions allows drying at lower temperatures, which is vital when dealing with heat-sensitive or volatile substances. This flexibility enhances compliance with stringent pharmaceutical standards.

Food and Feed Processing

You rely on paddle dryers in food and feed industries to dry ingredients, by-products, and wastes efficiently. The equipment’s versatility enables uniform drying of products like starches, proteins, fibers, and other bio-materials without losing nutritional value.

The indirect heating approach and mechanical mixing reduce the risk of scorching or thermal damage to the product. Also, paddle dryers adapt well to variable moisture contents and different material consistencies.

Their ability to handle sticky, lightweight, or pasty substances makes them suitable for drying sludge, food waste, and feed additives. This enhances product stability and extends shelf life while optimizing operational costs in processing plants.

Operational Advantages of Paddle Dryers

Paddle dryers offer specific benefits that improve your drying operations by reducing energy costs, ensuring consistent moisture removal, and protecting sensitive materials during the process. These advantages are critical to maximizing efficiency and product quality in various industrial settings.

Energy Efficiency

You can significantly lower your energy consumption with paddle dryers because they use indirect heating methods, often with thermal oil or saturated steam circulating inside hollow paddles. This system transfers heat efficiently, reducing the time needed to dry materials.

The design maximizes heat exchange while minimizing heat loss. This means you spend less on energy without sacrificing drying performance. Additionally, the compact construction conserves space and allows for more controlled thermal management, which contributes to operational savings.

Uniform Drying

Paddle dryers excel at providing consistent drying throughout your material batch. The paddles constantly stir the product, preventing clumping and promoting even heat distribution. This mechanical agitation helps remove moisture uniformly, reducing the risk of hot spots or under-dried areas.

Because of this continuous mixing, you achieve better product quality and fewer rejects. This uniformity is especially important when handling heterogeneous materials like sludge or powders, where inconsistent drying can affect downstream processing.

Gentle Material Handling

You preserve the integrity of delicate or heat-sensitive materials using paddle dryers. The indirect heating and controlled agitation minimize exposure to direct heat and mechanical stress, reducing the risk of degradation or damage.

This gentle approach makes paddle dryers suitable for pharmaceuticals, food products, and other sensitive goods. You can maintain product quality without compromising drying efficiency, which is essential when processing fine or fragile substances.

Key Performance Factors

You need to focus on how efficiently heat is transferred, the drying capacity of the machine, and the control you have over the time materials remain in the dryer. These aspects directly impact energy use, product quality, and operational flexibility.

Heat Transfer Mechanisms

Heat transfer in a paddle dryer occurs mainly through conduction and convection. The paddles and heating surfaces are typically heated indirectly by steam, hot oil, or thermal fluids. This indirect heating minimizes exposure of your material to direct flame or extreme temperatures.

Efficient paddle contact ensures uniform heat distribution and prevents material buildup. You must maintain clean paddles and seals to avoid heat loss. Proper insulation of the dryer vessel reduces energy waste and keeps temperature consistent inside.

Sealing mechanisms also matter because leaks can lower the heat transfer efficiency. If drying requires inert conditions, nitrogen can be introduced without affecting heat exchange significantly.

Drying Capacity

Drying capacity depends on the design of the dryer, paddle size, rotation speed, and heating method. You can increase capacity by optimizing paddle surface area and agitation to enhance contact between the material and heated surfaces.

Materials with higher moisture content or larger particle sizes may require adjustments in paddle speed or heating intensity. The dryer should handle feed rates that meet your production goals without compromising drying consistency.

You should consider the specific energy consumption, balancing drying rate with energy use. Using vacuum or dual-zone paddle dryers can improve capacity by enhancing moisture removal efficiency in complex processes.

Residence Time Control

Controlling how long your material stays in the paddle dryer is essential for achieving the desired dryness without overheating or under-drying. You do this by adjusting paddle speed, feed rate, and screw configuration when applicable.

Shorter residence times increase throughput but may reduce drying completeness. Longer times ensure thorough drying but at the risk of potential thermal degradation if temperature control isn’t precise.

You can fine-tune residence time based on the material’s heat sensitivity and moisture content. Monitoring and adjusting these parameters provide flexibility during process upsets or changes in raw material characteristics.

Installation and Maintenance

Proper installation and regular upkeep are essential for paddle dryers to function efficiently and last longer. You need to focus on precise assembly, system checks, and timely repairs to avoid operational delays and mechanical issues.

Installation Guidelines

Begin your installation by verifying that every component is complete and clean. Remove any foreign objects inside the dryer to prevent contamination and damage during operation.

Check the lubrication status, especially in the bearing seats, and add oil if necessary. The power supply must meet the equipment’s specifications to avoid electrical faults.

Install valves before the heating or cooling channels to control pressure and avoid over-pressure conditions. Ensure all pipe flanges align correctly; mismatched holes can cause leaks or structural instability.

Follow applicable standards when setting up the circuit system. Finally, verify hot water supply and return piping connections for proper thermal exchange without leaks or blockages.

Routine Maintenance

You should inspect paddle elements and bearings regularly to detect wear early. Lubricate bearings according to manufacturer recommendations to reduce friction and prolong service life.

Keep heat exchangers clean to maintain optimal thermal efficiency. Periodic calibration of control systems ensures accurate temperature and pressure regulation.

Make sure components are easily accessible for inspection and replacement, which reduces downtime. Using standardized parts aids in quicker repairs and consistent maintenance quality.

Monitor the system for unusual vibrations or noises, which often signal mechanical or alignment problems.

Troubleshooting Common Issues

If you notice flange misalignment or loose fittings, tighten connections and realign components before operation. Incorrect valve placement or missing pressure stabilizers can cause overpressure, risking damage.

Overheating may result from faulty temperature sensors or inadequate heat supply regulation. Check that thermal input stays within rated values to prevent equipment damage.

Unusual vibrations often indicate worn bearings or paddle imbalance. Inspect and replace parts as necessary to maintain stability.

Ensure proper cable tagging and sizing during installation to avoid electrical faults or system errors. Address these issues promptly to prevent costly downtime.

Safety and Environmental Considerations

You must address key aspects of emission control, operational safety, and waste management to ensure the paddle dryer functions effectively and complies with environmental and workplace standards. Each element requires specific measures to protect both operators and the surrounding environment.

Emission Control

Paddle dryers often feature an enclosed design that limits dust and vapor release during drying. This containment reduces risks of air pollution and protects workers from inhaling harmful particles.

To further control emissions, you can integrate filtration systems such as scrubbers or bag filters. These capture fine particulates and volatile organic compounds before they enter the atmosphere.

Implementing continuous monitoring of emissions ensures compliance with environmental regulations. Regular maintenance of seals and ducts also helps prevent leaks and uncontrolled releases.

Safe Operation Practices

Strict safety protocols are essential when operating paddle dryers. You must always follow lockout/tagout procedures during maintenance or repairs to prevent accidental startup.

Training is vital. Operators should be knowledgeable about mechanical functions, hot surface hazards, and confined space protocols. Awareness minimizes risks of burns, crush injuries, and exposure to harmful gases.

Always check equipment integrity and system controls before operation. Safety gear, including gloves and eye protection, should be worn consistently to reduce injury risks.

Waste Management Strategies

The drying process concentrates sludge or other materials, reducing volume but creating concentrated waste. You need to plan for proper handling and disposal of this dried sludge.

Compliance with local regulations on waste disposal or beneficial reuse is critical. You can explore options like land application, incineration, or further processing based on sludge composition.

Ensure waste storage areas are secure and designed to prevent runoff or environmental contamination. Regular audits of your waste management system maintain both safety and regulatory adherence.

Current Trends and Technological Innovations

You will find that recent advancements in paddle dryers focus on improving operational efficiency and enhancing integration within production lines. These improvements help optimize drying processes while reducing energy use and manual intervention.

Automation in Paddle Dryers

Automation in paddle dryers has become a key driver for improving consistency and reducing downtime. Modern systems often include programmable logic controllers (PLCs) that adjust drying parameters in real time based on moisture content and temperature feedback.

You gain precise control over drying times, reducing over-drying or under-drying risks. Automation also allows remote monitoring and data collection, enabling better maintenance planning and quick troubleshooting.

Energy consumption is often optimized through automated adjustments, which can reduce power use by up to 40% compared to older models. This means you can expect lower operating costs and improved system reliability.

Integration with Other Processing Equipment

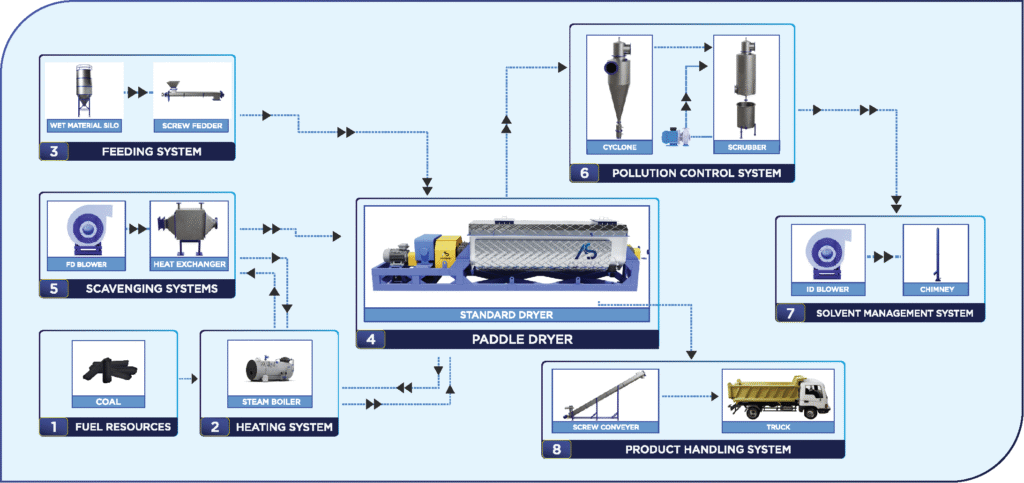

Integrating paddle dryers with upstream and downstream equipment streamlines production and minimizes manual handling. You can connect paddle dryers directly to mixers, reactors, or packaging lines to create seamless workflows.

This integration often involves synchronizing throughput rates and data sharing across systems. Real-time communication between devices helps prevent bottlenecks and ensures consistent product quality.

Furthermore, combining paddle dryers with complementary equipment improves material handling efficiency, reduces contamination risks, and supports more compact plant layouts. This approach enhances your overall process efficiency and scalability.

Choosing the Right Paddle Dryer

Selecting the appropriate paddle dryer depends on the specific characteristics of your material and the capabilities of the supplier. Key factors include the material type, moisture levels, and production requirements, alongside supplier expertise, technology, and service quality.

Selection Criteria

Focus on the material properties first: moisture content, particle size, and heat sensitivity are critical. These determine the drying method and temperature control you need.

Consider the final desired moisture content and your throughput capacity. The paddle dryer’s size and configuration must match your production volume to maintain efficiency.

Also, check for compatibility with your facility. Space availability and integration with existing systems can affect your choice.

Look for features like hollow shafts or slurry leaves if you’re drying sludge or sticky materials. These improve heat transfer and prevent buildup.

Supplier Evaluation

Choose suppliers with proven experience in your industry to ensure the machine fits your application. Request case studies or references.

Evaluate technology offerings, such as patented designs or energy-efficient components, which can improve performance and reduce costs.

Consider after-sales support, including installation, training, and maintenance. Reliable service minimizes downtime.

Compare pricing but weigh it against quality, warranty length, and availability of spare parts to avoid future issues.

Ask whether the supplier like the leading and top paddle dryer manufacturer AS Engineers offers customization and scalability options for future production changes.