The Ultimate Guide to Robot Types: Understanding Modern Robotics in 2025

Have you ever stopped to consider just how many robots you interact with in your daily life? From that smart vacuum quietly cleaning your living room to the industrial machines assembling your car, robots have seamlessly integrated into our world in ways both obvious and invisible. Yet for many of us, the vast landscape of robot types remains a mystery worth exploring.

The robotics industry is experiencing explosive growth, with the global market projected to reach $260 billion by 2030. This surge isn’t just about more robots—it’s about more kinds of robots revolutionizing everything from healthcare to space exploration. Whether you’re a tech enthusiast, industry professional, or just curious about the machines that increasingly shape our world, understanding the diverse ecosystem of robot types offers invaluable insight into our technological future.

In this comprehensive guide, we’ll explore the fascinating world of robot types, breaking down their classifications, capabilities, and real-world applications. You’ll discover how different robots work, what makes each category unique, and the cutting-edge innovations driving robotics forward in 2025 and beyond.

Table of Contents

Understanding Robot Fundamentals: Beyond Science Fiction

Before diving into specific robot types, let’s establish what actually constitutes a robot in today’s technological landscape. While science fiction has shaped our expectations of humanoid machines with personalities, the reality encompasses a much broader spectrum of devices.

What Defines a Robot?

At its core, a robot is a programmable machine capable of carrying out a complex series of actions automatically. Unlike simple machines or basic automated systems, true robots share several defining characteristics:

- Sensing capability: Robots use sensors to gather information about their environment

- Processing ability: They process this information to make decisions

- Actuation: Robots can physically interact with their environment based on processed information

- Programmability: They can be programmed to perform specific tasks or behaviors

- Autonomy: Modern robots exhibit varying degrees of independent operation

Dr. Ayanna Howard, Dean of Engineering at Ohio State University and robotics pioneer, explains: “What fundamentally separates robots from other machines is their ability to sense, think, and act with some degree of autonomy in unstructured environments.”

The Evolution of Modern Robotics

The journey from the first industrial robots to today’s sophisticated autonomous systems represents one of technology’s most fascinating evolutions:

- First Generation (1960s-1970s): Simple programmed machines with limited sensing capabilities, primarily used in manufacturing

- Second Generation (1980s-1990s): Enhanced sensing and adaptive capabilities, expanding into new industries

- Third Generation (2000s-2010s): Integration of advanced AI, enabling more autonomous decision-making

- Fourth Generation (2015-Present): Collaborative, socially aware robots with sophisticated learning capabilities

This evolution continues to accelerate as AI, sensor technology, and materials science open new frontiers for what robots can achieve and how they can interact with humans.

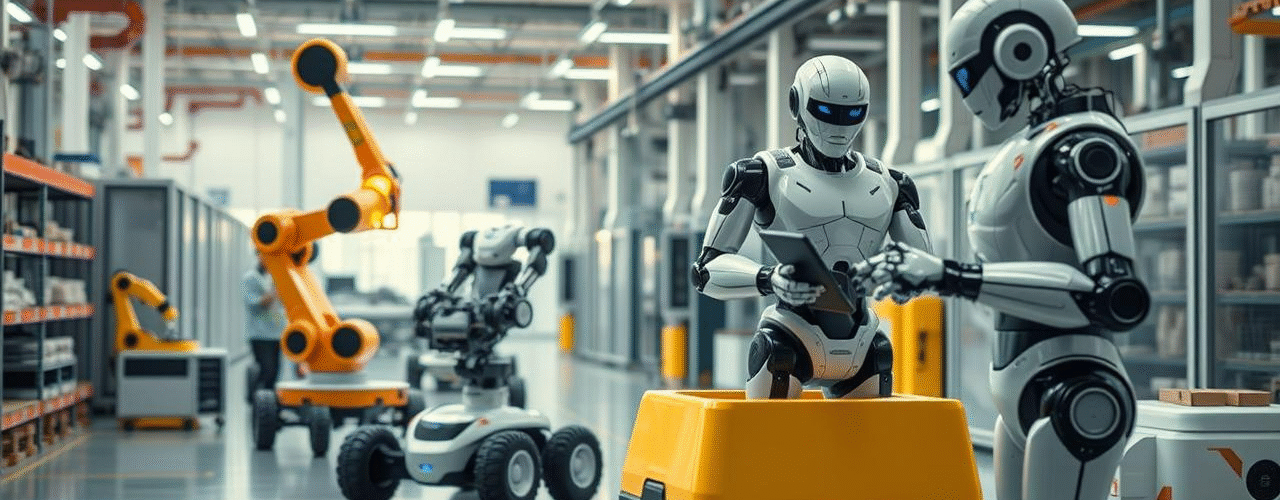

Industrial Robots: The Backbone of Automated Manufacturing

Industrial robots represent the oldest and most economically significant category of robotics, transforming manufacturing since the 1960s. These powerful machines continue to evolve in capability and application.

Major Types of Industrial Robots

Articulated Robots

With jointed arm structures resembling human arms, articulated robots dominate manufacturing environments. These versatile machines feature multiple joints (typically 4-7 axes of movement), allowing them to perform complex maneuvers in three-dimensional space.

Key applications include:

- Welding and painting automotive components

- Picking and placing electronic components

- Assembling consumer products

- Material handling in harsh environments

The latest generation of articulated robots, like ABB’s IRB series, can lift payloads exceeding 1,000 kg while maintaining positioning accuracy to within 0.1mm.

SCARA Robots

Selective Compliance Assembly Robot Arms (SCARA) offer rigid vertical movement with flexible horizontal mobility, making them ideal for precise assembly operations.

Primary uses:

- Circuit board population

- Small parts assembly

- Pick-and-place operations requiring high speed

- Laboratory automation

SCARA robots excel in applications requiring high-speed, repetitive movements in a plane, with cycle times often under 0.5 seconds for standard pick-and-place operations.

Delta Robots

These spider-like robots feature parallel link structures that allow for incredible speed and precision in lightweight applications.

Common applications:

- Food sorting and packaging

- Pharmaceutical product handling

- High-speed pick-and-place operations

- Visual inspection systems

Delta robots from companies like Fanuc can achieve speeds exceeding 200 picks per minute, making them the fastest industrial robots available.

Cartesian/Gantry Robots

Using linear actuators along the X, Y, and Z axes, these robots provide highly accurate positioning across their entire work envelope.

Typical uses:

- CNC machining

- 3D printing

- Large-scale material handling

- Automated storage and retrieval systems

The modular nature of Cartesian robots allows for customized work areas spanning from desktop-sized to entire factory floors.

Collaborative Industrial Robots (Cobots)

The latest revolution in industrial robotics comes in the form of collaborative robots, or cobots, designed to work safely alongside human operators without protective barriers.

Cobots like Universal Robots’ UR series incorporate advanced force-sensing technologies and rounded surfaces to detect and prevent harmful impacts. This allows them to share workspaces with humans while handling tasks requiring both precision and flexibility.

“Cobots represent a fundamental shift in industrial automation,” notes Dr. Julie Shah, Associate Professor at MIT’s Department of Aeronautics and Astronautics. “Rather than replacing human workers entirely, these systems complement human capabilities, handling repetitive tasks while people focus on elements requiring creativity and problem-solving.”

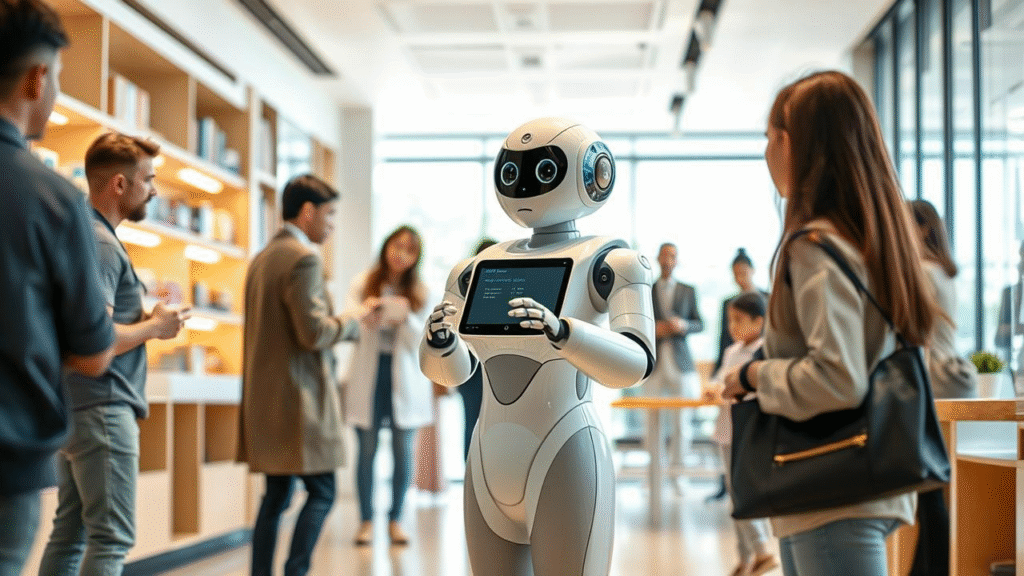

Service Robots: Automating Everyday Tasks

While industrial robots transform manufacturing, service robots are changing how we handle everyday tasks across commercial, public, and domestic environments.

Professional Service Robots

These specialized machines perform services outside of manufacturing settings, often in professional or commercial environments.

Healthcare Robots

The healthcare sector has embraced robotics for tasks ranging from surgical assistance to patient care:

- Surgical robots: Systems like Intuitive Surgical’s da Vinci platform enable minimally invasive procedures with enhanced precision. These telemanipulation systems translate a surgeon’s hand movements into micro-precise instrument movements inside the patient.

- Pharmacy automation robots: Machines like Omnicell’s XR2 Automated Central Pharmacy System can prepare and dispense thousands of prescriptions daily with near-perfect accuracy.

- Disinfection robots: UV-C emitting robots like those from UVD Robots can disinfect hospital rooms in minutes, reducing healthcare-associated infections by up to 99.9%.

- Care robots: Assistive robots help with patient mobility, monitoring, and even social interaction for elderly or disabled individuals.

Agricultural Robots

Smart farming increasingly relies on specialized robots for efficient and sustainable agricultural practices:

- Harvesting robots: Machines like Harvest CROO’s strawberry harvester use computer vision to identify ripe fruit and gently pick it without damage.

- Weeding robots: Autonomous systems like FarmWise’s Titan eliminates weeds through precision mechanical methods, reducing herbicide usage by up to 95%.

- Crop monitoring drones: Flying robots equipped with multispectral cameras assess crop health across vast fields, identifying disease or irrigation issues before they become visible to the human eye.

Logistics and Delivery Robots

The logistics sector has been transformed by robots handling everything from warehouse operations to last-mile delivery:

- Warehouse robots: Amazon’s fleet of over 350,000 mobile robots transport inventory throughout massive fulfillment centers, while companies like Boston Dynamics offer more versatile mobile manipulation robots for complex logistics tasks.

- Autonomous delivery vehicles: Sidewalk robots from Starship Technologies and aerial delivery drones from companies like Wing are making contactless delivery increasingly common in urban areas.

Personal and Domestic Service Robots

These consumer-focused robots have found their way into millions of homes worldwide.

Household Cleaning Robots

From floors to windows, cleaning robots tackle specific household maintenance tasks:

- Robot vacuums: Advanced models like the Roomba j9+ incorporate AI mapping, object recognition, and self-emptying capabilities.

- Window cleaning robots: Devices like HOBOT use suction technology to safely navigate and clean vertical glass surfaces.

- Lawn mowing robots: Autonomous mowers like Husqvarna’s Automower series maintain lawns with precision edge cutting and obstacle avoidance.

Social and Companion Robots

These robots focus on interaction and emotional connection:

- Elder care companions: Robots like PARO the therapeutic seal provide comfort and cognitive stimulation for elderly individuals, particularly those with dementia.

- Educational robots: Platforms like LEGO MINDSTORMS and Sphero combine entertainment with STEM education, teaching programming and robotics concepts.

“The most successful domestic robots solve specific problems extremely well rather than trying to be generalists,” explains robotics entrepreneur Colin Angle, CEO of iRobot. “This focused approach allows them to deliver tangible value within the technical constraints of current technology.”

Mobile Robots: Intelligence on the Move

Mobile robots demonstrate perhaps the most visible advancement in autonomous capabilities, navigating complex environments without human intervention.

Autonomous Ground Vehicles (AGVs and AMRs)

Ground-based mobile robots have evolved from simple programmed path-followers to sophisticated autonomous systems:

- Automated Guided Vehicles (AGVs): These traditional systems follow fixed paths defined by magnetic strips, wires, or visual markers. They excel in structured environments like factories where predictable routes remain constant.

- Autonomous Mobile Robots (AMRs): The newer generation of ground robots uses advanced sensing and AI to navigate dynamically, planning and adjusting paths as they encounter obstacles. Unlike AGVs, AMRs require minimal infrastructure changes to deploy.

Companies like Fetch Robotics and MiR have developed flexible platforms that can be adapted for multiple applications, from warehouse inventory movement to hospital supply delivery, simply by changing the attachments or software configuration.

Unmanned Aerial Vehicles (UAVs/Drones)

From consumer quadcopters to military reconnaissance platforms, aerial robots have experienced explosive growth:

- Consumer drones: Used primarily for photography and recreation, these accessible flying robots from companies like DJI incorporate sophisticated stabilization systems and automated flight modes.

- Commercial inspection drones: Specialized UAVs inspect infrastructure like power lines, wind turbines, and bridges, accessing dangerous locations without putting humans at risk.

- Agricultural drones: Equipped with multispectral sensors, these platforms can survey hundreds of acres daily, providing insights on crop health impossible to gather from ground level.

- Delivery drones: Companies like Wing (Alphabet) and Amazon Prime Air continue developing systems for rapid aerial delivery of small packages.

“The regulatory framework is finally catching up with drone technology,” notes Lisa Ellman, Chair of the Global UAS Group at Hogan Lovells and former Obama Administration advisor. “We’re seeing the integration of advanced drone operations into national airspace worldwide, enabling applications that were merely theoretical five years ago.”

Autonomous Underwater Vehicles (AUVs)

These underwater robots explore depths inaccessible or too dangerous for human divers:

- Research AUVs: Platforms like Woods Hole Oceanographic Institution’s REMUS vehicles gather oceanographic data at depths exceeding 6,000 meters.

- Pipeline and infrastructure inspection: Specialized underwater robots inspect offshore oil platforms, dams, and underwater cables.

- Environmental monitoring: AUVs track pollution, map coral reefs, and monitor marine wildlife populations.

Advancements in battery technology and underwater communication systems continue extending the range and capabilities of these sophisticated underwater robots.

Humanoid Robots: Machines in Our Image

Perhaps no robot type captures the imagination quite like humanoids—robots designed with bodies that resemble the human form. While these machines face enormous engineering challenges, they continue advancing toward more capable and natural interaction.

The Purpose Behind Human-like Design

Humanoid robots aren’t just built this way for aesthetic reasons. The human form offers specific advantages:

- Environment compatibility: Our world is designed for human bodies, with doorknobs at certain heights, stairs of specific dimensions, and tools made for human hands.

- Natural interaction: Humans instinctively understand body language, facial expressions, and physical gestures, making humanoid robots potentially more intuitive to interact with.

- Versatility: The human form combines remarkable mobility with manipulation capabilities, allowing navigation and interaction with countless objects.

Leading Humanoid Platforms

Several groundbreaking humanoid projects demonstrate the current state of the art:

- Boston Dynamics Atlas: This hydraulically powered humanoid demonstrates unprecedented dynamic movement, including running, jumping, backflips, and parkour. While primarily a research platform, it showcases the potential for humanoid mobility.

- NASA’s Valkyrie: Designed initially for disaster response, this 6-foot tall, 300-pound humanoid focuses on robust manipulation capabilities in unstructured environments.

- Engineered Arts’ Ameca: Featuring remarkably expressive facial movements, Ameca represents advances in human-robot interaction through realistic non-verbal communication.

- Tesla’s Optimus: Announced in 2021 and showcasing prototypes in 2022-2024, Tesla’s humanoid aims to become a general-purpose robot for everyday tasks, leveraging the company’s expertise in AI and manufacturing.

Challenges in Humanoid Development

Despite impressive demonstrations, humanoid robots still face significant limitations:

- Power constraints: Human-scale robots require substantial energy for locomotion and manipulation, limiting operational time.

- Dexterity gap: Human hands remain vastly more capable than robotic end effectors, particularly for manipulating unknown objects.

- Complexity and cost: The intricate systems required for full-body humanoids make them exponentially more expensive than single-purpose robots.

“The humanoid form represents the ultimate challenge in robotics,” explains Dr. Dennis Hong, Professor and Director of RoMeLa at UCLA. “While we’ve made remarkable progress in specific aspects like locomotion or facial expression, creating a truly general-purpose humanoid remains our field’s moonshot.”

Micro and Nanorobots: The Smallest Machines

At the opposite end of the size spectrum, microscopic robots represent one of robotics’ most promising frontiers, particularly for medical applications.

Medical Microrobots

These tiny machines, often smaller than a millimeter, hold potential for revolutionary medical treatments:

- Drug delivery: Microrobots can transport medication directly to targeted tissues, potentially transforming cancer treatment by reducing systemic side effects.

- Minimally invasive surgery: Tiny robots could perform procedures inside the body without external incisions.

- Diagnostic imaging: Swallowable or injectable robots equipped with sensors can provide internal imaging previously requiring invasive procedures.

Research teams at institutions like ETH Zurich and the Max Planck Institute have developed magnetically controlled microrobots capable of navigating through bodily fluids with precision.

Swarm Robotics

Inspired by social insects like ants and bees, swarm robotics involves coordinating large numbers of relatively simple robots to accomplish complex tasks:

- Harvard’s Kilobots: These quarter-sized robots demonstrate how simple units can self-organize into sophisticated collective behaviors.

- Drone swarms: Multiple coordinated UAVs perform complex aerial displays or mapping operations impossible for single units.

Professor Radhika Nagpal, a pioneer in swarm robotics at Harvard and Princeton, explains: “The power of swarm systems comes not from individual capability but emergent behavior—simple rules at the individual level creating sophisticated group intelligence.”

Specialized Robot Types: Purpose-Built Solutions

Beyond the major categories, numerous specialized robot types address specific applications with unique designs and capabilities.

Soft Robots

Unlike traditional rigid robots, soft robots use flexible materials that can bend, stretch, and adapt to their environment:

- Medical applications: Soft grippers can handle delicate tissues without damage.

- Search and rescue: Adaptable soft robots can squeeze through rubble in disaster scenarios.

- Underwater exploration: Soft robots like Harvard’s octobot can navigate complex underwater environments without damaging fragile ecosystems.

Exoskeletons

These wearable robots augment human capabilities rather than replacing human operators:

- Medical rehabilitation: Exoskeletons help patients with spinal cord injuries regain mobility.

- Industrial support: Workers use powered exoskeletons to reduce strain when lifting heavy objects or performing repetitive tasks.

- Military applications: Soldier-worn systems reduce fatigue during load carriage and long marches.

Teleoperated Robots

These remotely controlled systems extend human capabilities into dangerous or inaccessible environments:

- Bomb disposal: EOD robots like the TALON allow technicians to examine and neutralize explosive devices from a safe distance.

- Nuclear operations: Special manipulators handle radioactive materials without exposing workers to radiation.

- Deep sea exploration: ROVs (Remotely Operated Vehicles) explore ocean depths beyond human diving limits.

The Future of Robot Types: Emerging Trends and Technologies

The robotics landscape continues evolving rapidly, with several key trends shaping the next generation of robot types.

AI and Machine Learning Integration

While robots have traditionally excelled at repetitive, predefined tasks, modern AI is enabling unprecedented adaptability:

- Reinforcement learning: Robots like Google DeepMind’s robotic arm learn complex manipulation skills through trial and error.

- Computer vision advances: Deep learning algorithms enable robots to recognize and appropriately handle previously unseen objects.

- Natural language interaction: Voice-controlled robots can understand complex verbal instructions and provide contextual responses.

“The combination of robust hardware with advanced AI represents a fundamental shift in capability,” notes Dr. Dieter Fox, Senior Director of Robotics Research at NVIDIA. “We’re moving from robots that perform singular tasks well to systems that can reason about their environment and solve novel problems.”

Bioinspired Design

Nature’s 3.8 billion years of evolutionary R&D continues inspiring novel robot designs:

- Animal-inspired locomotion: Boston Dynamics’ Spot draws from quadruped animal movement for unprecedented mobility on irregular terrain.

- Biomimetic materials: Synthetic muscles and tendons replicate biological efficiency and compliance.

- Sensory systems: Robot perception increasingly mimics animal sensing, from whisker-inspired tactile sensors to echolocation-like systems.

Human-Robot Collaboration

Perhaps the most significant trend is the shift from robots as replacements for humans to robots as partners:

- Intuitive programming: Modern robots can learn new tasks through demonstration rather than complex coding.

- Adaptive safety systems: Advanced sensors enable robots to work alongside humans without cages or barriers.

- Augmented intelligence: Robots handle physical tasks while leveraging human judgment for complex decisions.

Ethical and Societal Implications of Robot Types

As robots become more capable and widespread, their development raises important questions for society.

Employment Impact

While robots create new jobs in design, programming, and maintenance, they also automate certain roles:

- Complementary tasks: Most successful implementations pair robot efficiency with human creativity and judgment.

- Skill transition: Educational systems and companies must help workers develop skills for the changing workplace.

- New opportunities: Robot deployment often creates entirely new business models and service categories.

Privacy and Security Concerns

As robots incorporate more sensors and AI capabilities, they raise important privacy questions:

- Data collection: Household and public robots gather enormous amounts of environmental data.

- Cybersecurity: Connected robots represent potential security vulnerabilities if not properly protected.

- Surveillance potential: Mobile robots with advanced sensing capabilities could enable unprecedented monitoring.

Autonomy and Decision-Making

As robots make more complex decisions, questions arise about appropriate limits:

- Safety-critical decisions: Should robots make life-or-death decisions in contexts like autonomous vehicles or medical care?

- Algorithmic bias: How do we ensure robot decision-making doesn’t perpetuate existing social biases?

- Transparency: Can complex AI decision processes be made understandable to the humans affected by them?

FAQs About Robot Types

What is the difference between a robot and an AI system?

While closely related, robots and AI systems differ fundamentally. A robot is a physical machine that can sense and interact with the real world through mechanical components. AI systems are software programs that process information and make decisions. Many modern robots incorporate AI, but not all AI systems control robots. Your smartphone assistant uses AI but isn’t a robot because it lacks physical manipulation capabilities.

Can robots truly be autonomous, or do they always require human oversight?

Robot autonomy exists on a spectrum rather than as a binary state. Simple robots like vacuum cleaners operate with minimal oversight but within narrowly defined parameters. More advanced systems like self-driving vehicles demonstrate higher autonomy but still require human backup in certain scenarios. Complete autonomy—where robots make all decisions without any human input or design constraints—remains theoretical. Even the most advanced autonomous robots today operate within parameters established by human designers.

How are robot types classified in scientific literature?

Scientific classification of robots typically follows several overlapping taxonomies:

- By application domain (industrial, service, military)

- By locomotion method (wheeled, legged, aerial, underwater)

- By control architecture (teleoperated, semi-autonomous, autonomous)

- By form factor (humanoid, animal-inspired, non-biomimetic)

- By operating environment (structured, semi-structured, unstructured)

What robot types are experiencing the fastest growth in 2025?

Based on market analysis, the fastest-growing robot categories include:

- Collaborative industrial robots (cobots)

- Autonomous mobile robots for logistics

- Healthcare assistance robots

- Agricultural robots for precision farming

- Advanced household robots beyond simple vacuuming

How do I determine which robot type is appropriate for my application?

Selecting the right robot type involves analyzing several factors:

- Task requirements (precision, speed, payload)

- Operating environment (structured vs. unstructured)

- Safety needs (will humans work alongside the robot?)

- Return on investment timeline

- Integration with existing systems

- Available expertise for programming and maintenance

For specific applications, consulting with robotics integration specialists can help match requirements with appropriate robot types.

Conclusion: The Expanding Universe of Robot Types

As we’ve explored throughout this guide, “robot” has evolved from a singular concept to a vast ecosystem of specialized machines transforming virtually every aspect of human activity. From microscopic medical robots to massive industrial systems, each type addresses specific challenges while advancing the overall field.

What makes robotics particularly fascinating is how quickly the boundaries between categories blur. Industrial robots gain mobility, service robots incorporate industrial precision, and all systems benefit from the rapid advancement of AI capabilities. This cross-pollination drives innovation at an accelerating pace.

For businesses, understanding the landscape of robot types isn’t just academic—it’s increasingly crucial for maintaining competitiveness. For individuals, this knowledge provides insight into the technologies reshaping our workplaces, homes, and public spaces.

As we look toward the future, the most exciting developments will likely emerge not from refinements to existing robot types but from entirely new categories we haven’t yet imagined. The robotics revolution isn’t slowing down—it’s just getting started.

What has your experience been with robots in your daily life or work? Have you encountered any of the robot types discussed in this article? Share your thoughts or questions in the comments below!

Author’s Note: This comprehensive guide to robot types was last updated in April 2025. While we strive for accuracy, the robotics field evolves rapidly. For the most current information on specific robot models or emerging categories, consult manufacturer specifications or industry publications.